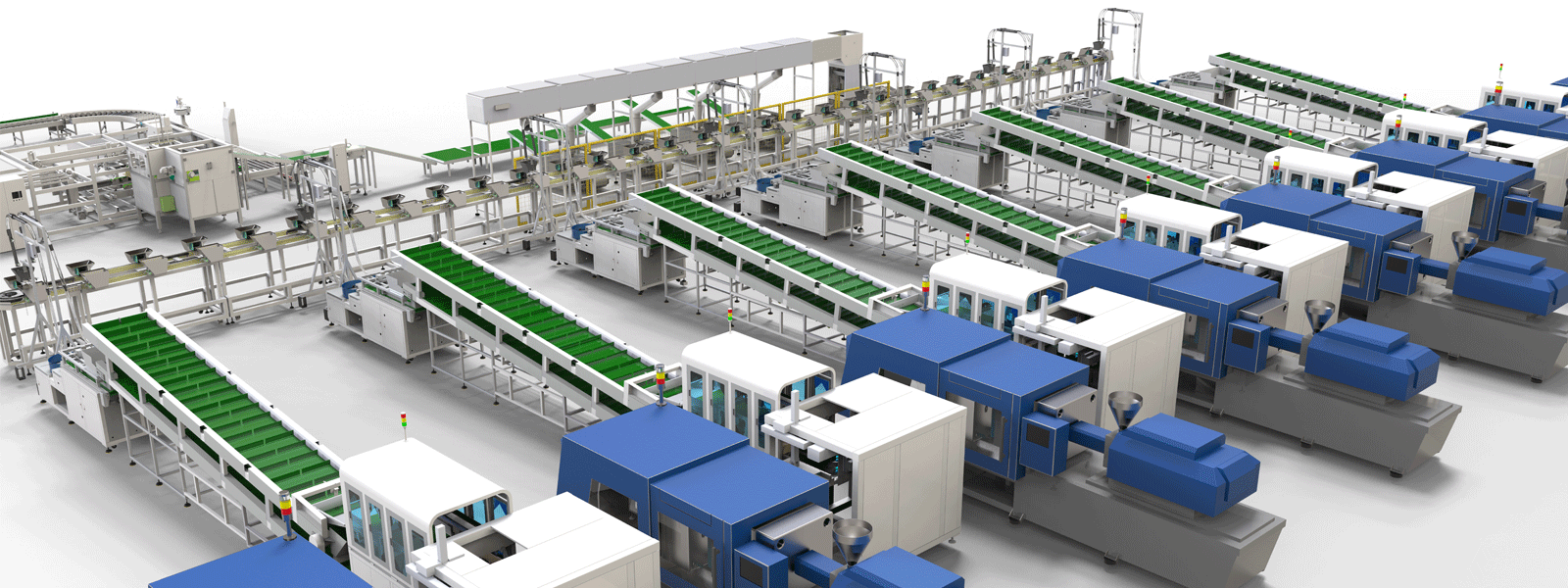

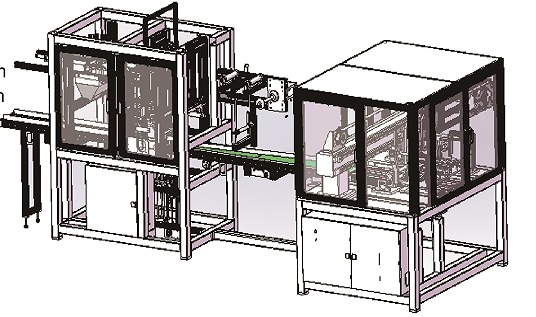

Petri Dish Automation Solution

Our state-of-the-art Petri Dish Automation Solution is designed to streamline the production, packaging, and inspection of Petri dishes. Offering top-in and side-entry options, this comprehensive system ensures high efficiency and superior quality throughout the manufacturing process. Whether you require injection molding, mold design, automated extraction, packaging, or inspection, our solution provides everything you need for a fully automated Petri dish production line.

Description

Benefits & Features

- Top-in and Side-Entry Options: Flexible entry methods to suit various production requirements.

- High Efficiency and Quality: Ensures consistent, high-quality production with minimal downtime.

- Complete Automation: From injection molding to automated extraction, packaging, and inspection, our solution covers every aspect of Petri dish production.

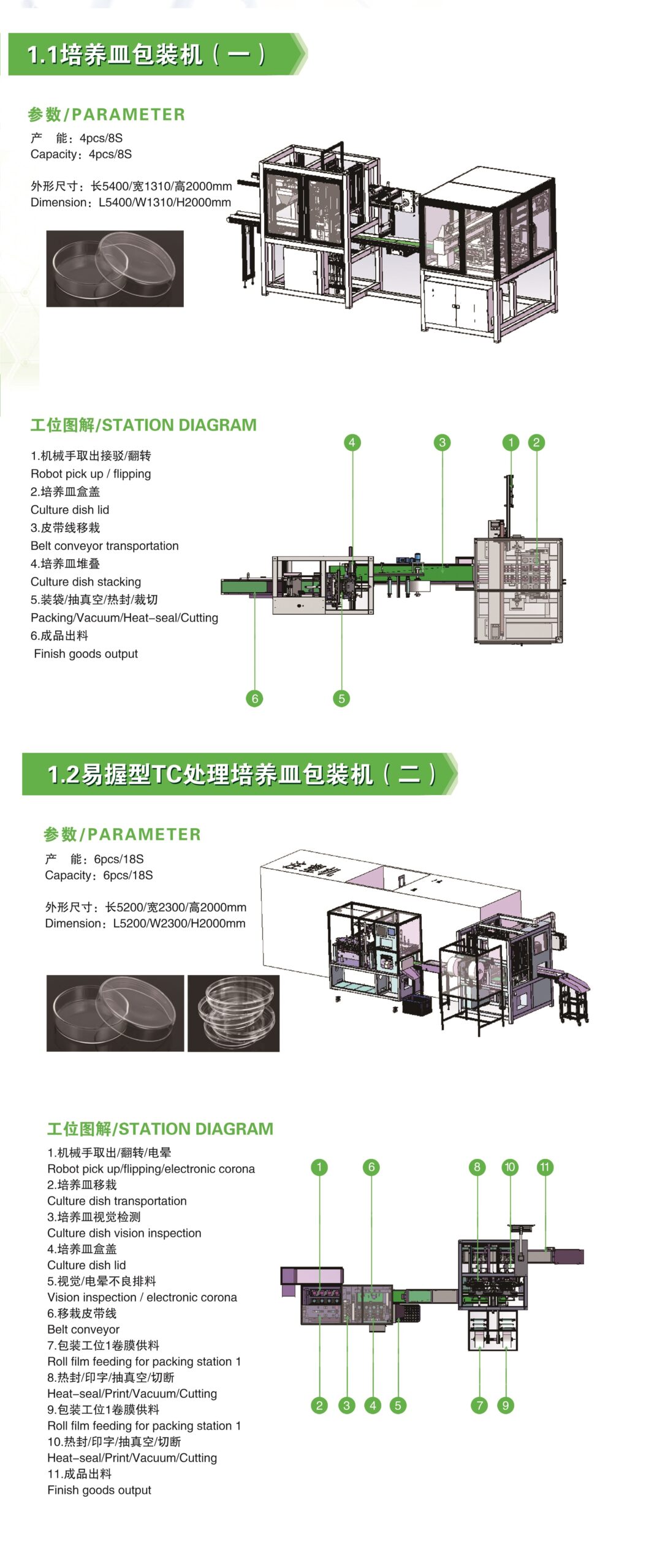

Configuration

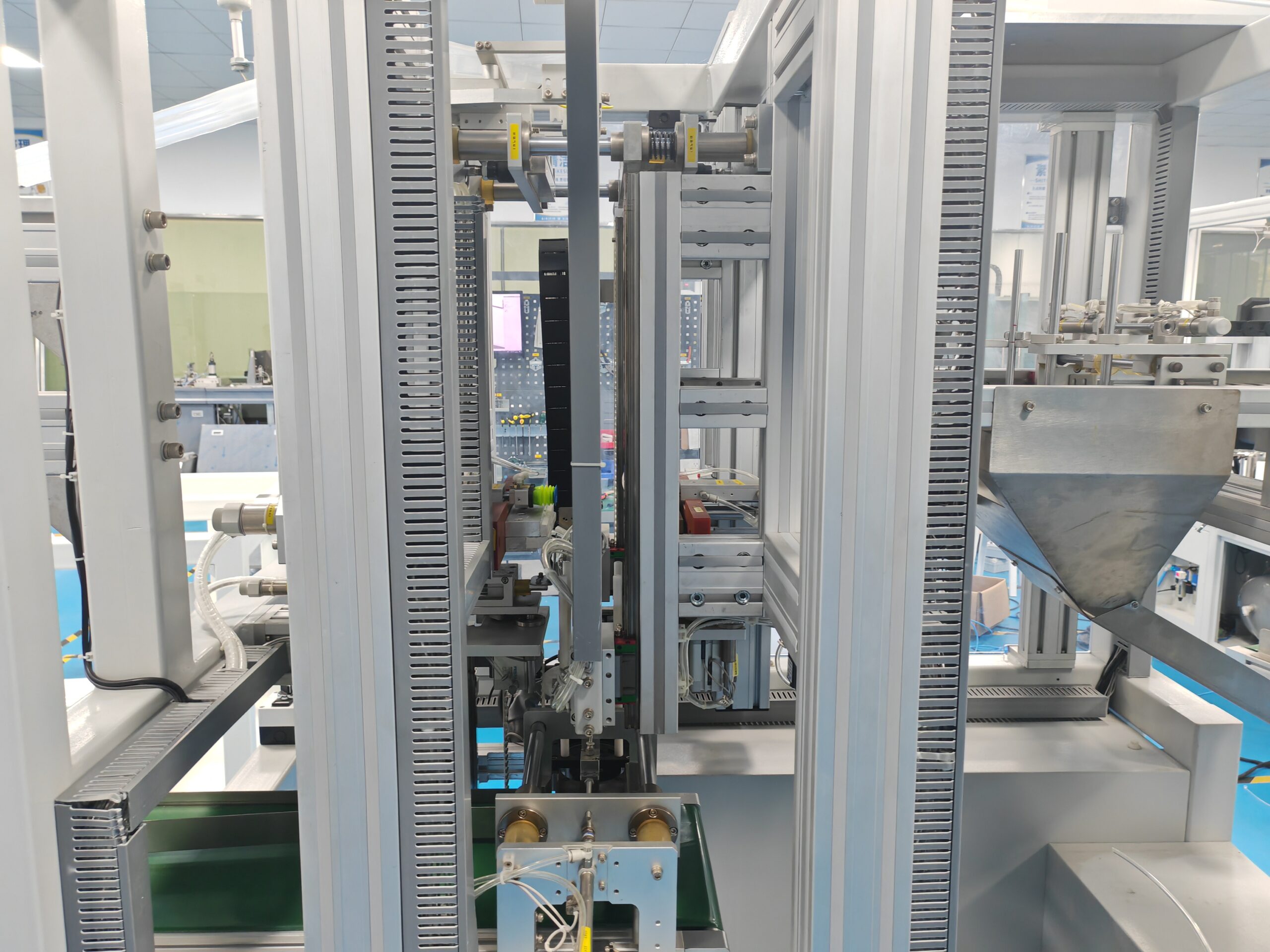

- Tilting System: Ensures precise handling and positioning of Petri dishes during the manufacturing process.

- Unwinding Mechanism: Efficiently manages the unwinding of materials, maintaining a steady production flow.

- Resin Storage Mechanism: Provides reliable storage and dispensing of resin for continuous production.

- Bagging Mechanism: Automates the packaging of Petri dishes, ensuring each bag contains 20 pieces.

- Finished Product Retrieval Mechanism: Streamlines the retrieval of finished products, enhancing overall production efficiency.

Comprehensive Automation Solutions

Our Petri Dish Automation Solution is designed to meet the diverse needs of the laboratory and medical industries. By integrating advanced automation technologies, we deliver a seamless, end-to-end production line that maximizes productivity and ensures the highest standards of quality.

- Injection Molding: Precision-engineered molds and state-of-the-art injection molding machines ensure accurate and consistent production of Petri dishes.

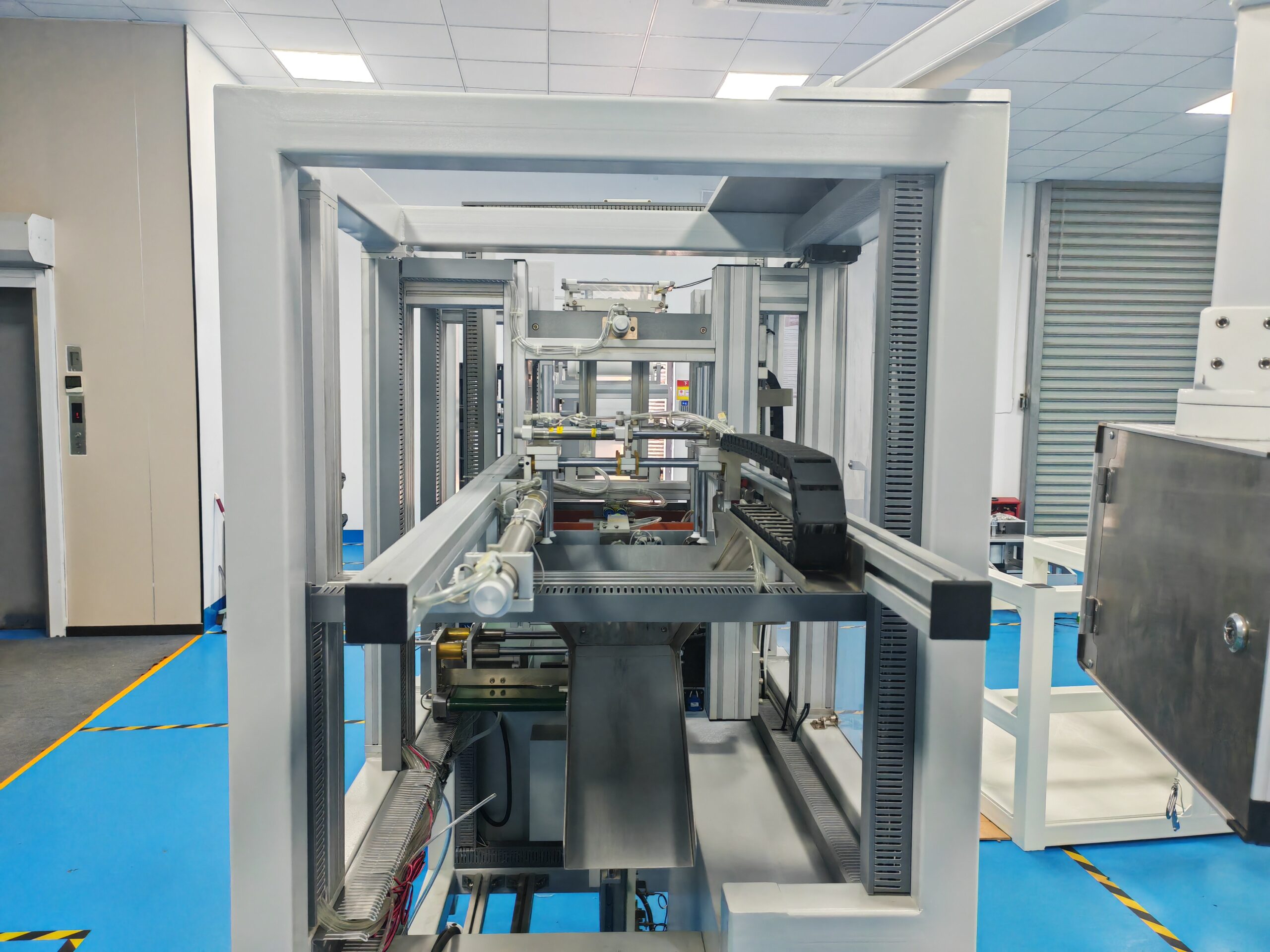

- Automated Extraction: High-speed, automated extraction systems enhance production efficiency and reduce manual labor.

- Automated Packaging: Our packaging solutions ensure that Petri dishes are securely packaged and ready for distribution.

- Automated Inspection: Advanced inspection technologies guarantee that each Petri dish meets stringent quality standards before packaging.

Benefits

- Increased Productivity: Automated systems significantly reduce production time and labor costs.

- Enhanced Quality Control: Consistent quality checks throughout the production process ensure that only the highest quality products are delivered.

- Flexibility: Our system can be customized to meet specific production requirements, offering both top-in and side-entry options.

- Cost-Effective: By reducing manual labor and increasing efficiency, our automation solution provides a cost-effective alternative to traditional manufacturing methods.

Specs

Note: Non-Standard Equipment cn be Customized according to the capacity of Injection Machine and requirements.

Cases

Application Category

https://youtube.com/shorts/mK3Dg4x5frI

https://youtu.be/ZkzHBEbppC4

Other Cases

Machine Disptach

Comments