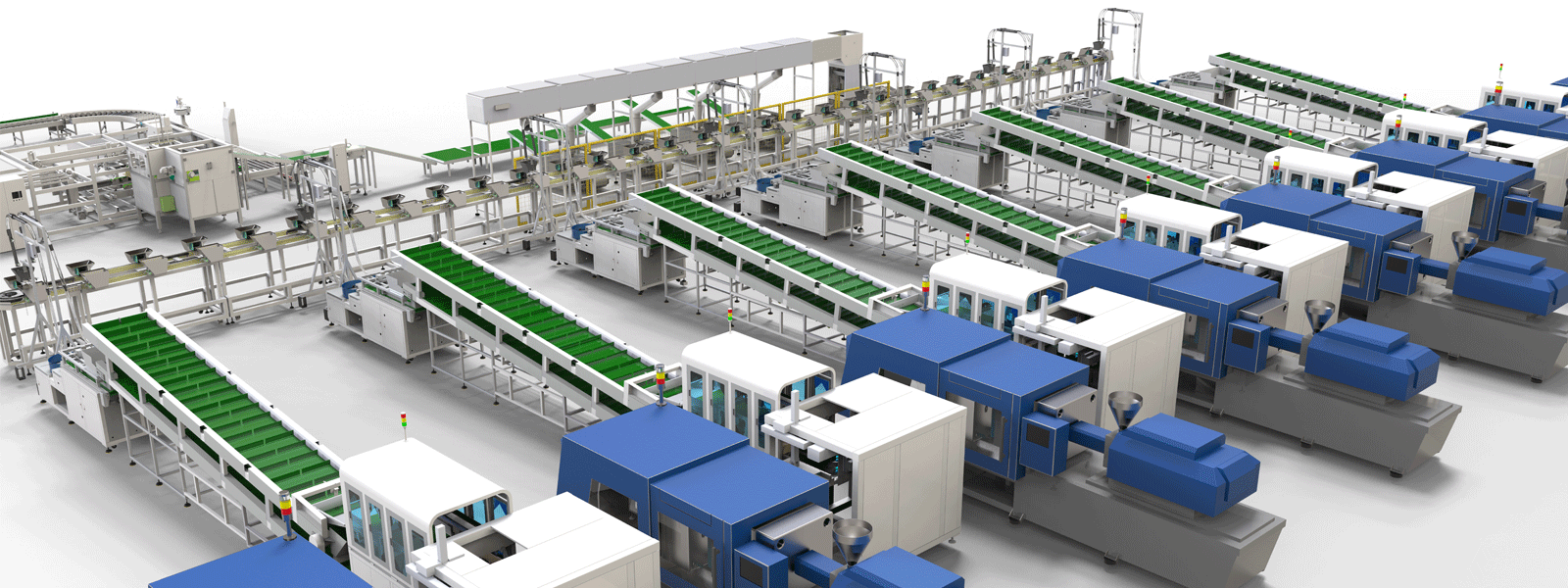

Micro Blood Collection Tube Production Line

The Micro Blood Collection Tube Production Line automates the processing of tube loading, dosing, capping, and packing, improving workflow efficiency with minimal personnel required.

Description

The Micro Blood Collection Tube Production Line by SANTSAI streamlines the production of micro blood collection tubes, making the process efficient and automated. Designed to collect blood from the fingertip, earlobe, or heel, this production line is ideal for neonates and pediatric patients. It handles tube loading, dosing, capping, and packing automatically, ensuring a smooth workflow with a one-piece production line that requires only a few operators.

Features and Advantages

- High Degree of Automation: Fully automatic assembly with optimized processes, from capping to finished product output. Requires only 1-2 skilled operators.

- High Cost Performance: Modular design and compact structure allow for automatic assembly based on actual production needs.

- Human-Machine Interaction: User-friendly interface with multi-function alarm and auxiliary troubleshooting.

- Process and Quality Control: Includes detection for material shortage, dosing action, drying temperature, cap placement, and missing caps, ensuring a high qualified rate.

- Precise Dosing System: Targeted dosing with ultrasonic automatic cleaning nozzle function.

- Ultrasonic Automatic Cleaning Nozzle: Designed with a drying function, adjustable cleaning frequency, eliminating the need for manual cleaning.

- Robust Construction: Made of SUS304 material, with a nano-processed frame and doors, and a high-rigidity steel structure for excellent shock absorption.

Specs

Configuration Description

| Pneumatic | AIRTAC cylinder, solenoid valve, shangshun cylinder and other pneumatic components are used to ensure stable operation and long life. |

| Electrical appliances | Original Schneider (France) electrical appliances, Omron (Japan) and Leuze (Germany) testing originals, Mitsubishi (Japan) PLC, Siemens (Germany) man-machine interface, Panasonic (Japan) servo motor. |

| Dosing device | American FMI ceramic metering pump, domestic precision ceramic injection pump. (the plan has only one dosing station). |

| Main components | The material is made of stainless steel sheet metal, the frame and door are nano-processed, the steel structure frame, high-quality aluminum alloy, stable and reliable and easy to clean, in line with GMP requirements. |

Technical Parameters

Item | Description |

| Applicable tube specification | Flat bottom micro tube. (based on the samples provided, four sets) |

| Production capacity | ≥ 5500 pieces / hour |

| Dosing method and precision | 2 nozzles FMI ceramic quantitative pump (air atomization) ≤ ± 6% (calculation base 10µL) |

| Drying method | 1 group, “PTC” heating, hot air drying |

| Power supply | 380V / 50HZ |

| Power | Assembly line ~ 6 KW |

| Clean compressed air pressure | 0.6-0.8Mpa |

| Air consumption | <300L / min, air inlet G1 / 2, air pipe Ø12 |

| Equipment dimension: length, width and height | 3000 (+ 1000) * 1200 (+ 1000) * 2000 (+ 300 alarm light) mm |

Note: Non-Standard Equipment cn be Customized according to the capacity of Injection Machine and requirements.

Cases

Application Category

Other Cases

Machine Disptach

Comments