Semi-automatic blow molding machine

Semi-automatic , VOL:1.5L ; CY:2500 Pcs/h

Description

Benefits & Features

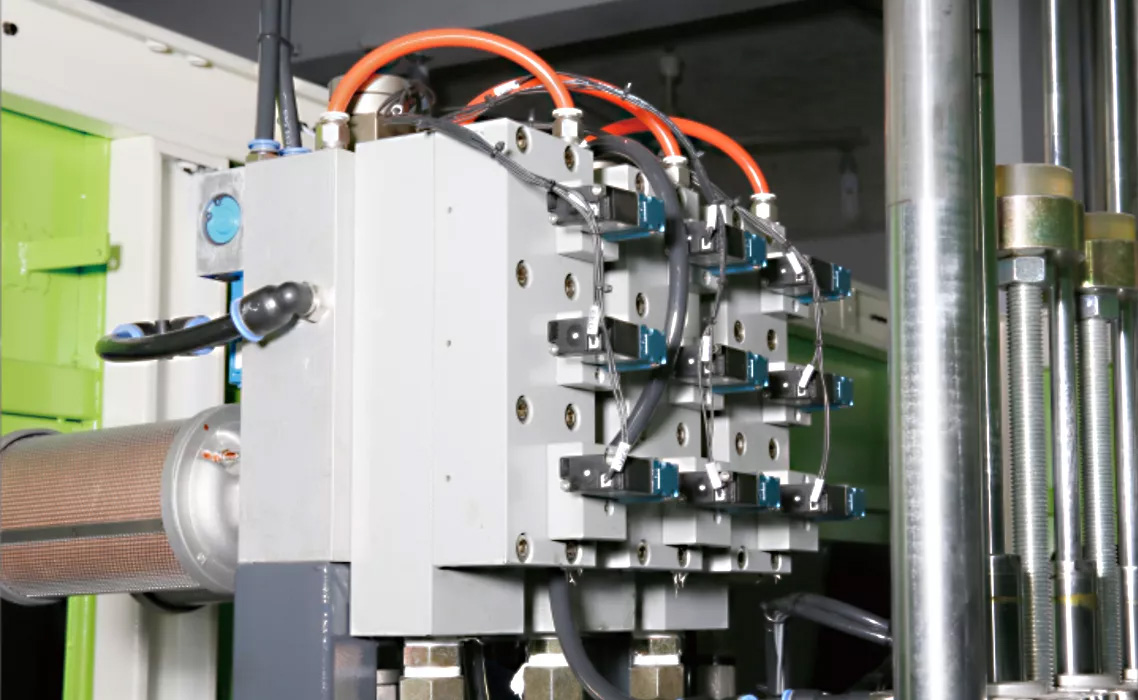

• Double crank arm for mold locking reaches high mold-locking strength and flexible action

• Use PLC for control (time relay control optional), easy repair, low cost, with the time controllable accurately in 0.01s..

• The gas circuit consists of moving and blowing so as to satisfy the different air demand of them .

• The far-infrared heater uses a way of conversion self-rotating heating and the rail revolution makes the heating even, quick and reliable.

• Every heating lamp has independent temperature control device, to get ideal preform heating effect

• The direction of the heating lamp is adjustable upon different preforms.

• Only need one operator, do not need special training. Simple installing and starting.

Specs

| Items | Unit | STSMS-4 |

| Theoretical output | Pcs/hr | 2500 |

| Volume | L | 1.5 |

| Max. height | mm | 360 |

| Max. diameter | mm | 105 |

| Number of cavities | / | 4 |

| Mould plate dimension(LxH) | mm | 700×420 |

| Mould thickness | mm | 240 |

| Mould opening stroke | mm | 200 |

| Power | 220-380V/50-60Hz | |

| Total power | KW | 21 |

| Heating power | KW | 20 |

| Main body dimension(LxWxH) | M | 1.9×0.85×2.25 |

| Main body weight | KG | 750 |

| Preform Autoloader(LxWxH) | M | 1.8×0.60×1.4 |

| Preform Autoloader weight | KG | 350 |

| Bottle Conveyor(LxWxH) | M | 2.0×0.60×1.1 |

| Bottle Conveyor weight | KG | 80 |

Cases

Application Category

Other Cases

Machine Disptach

Comments