SE-1900V Electric Injection

Capacity:40Ton~650 Ton

Intelligent PC & Network

Energy Saving

High Efficiency & Short Cycle

Environmental Low Consumption

Description

Benefits & Features

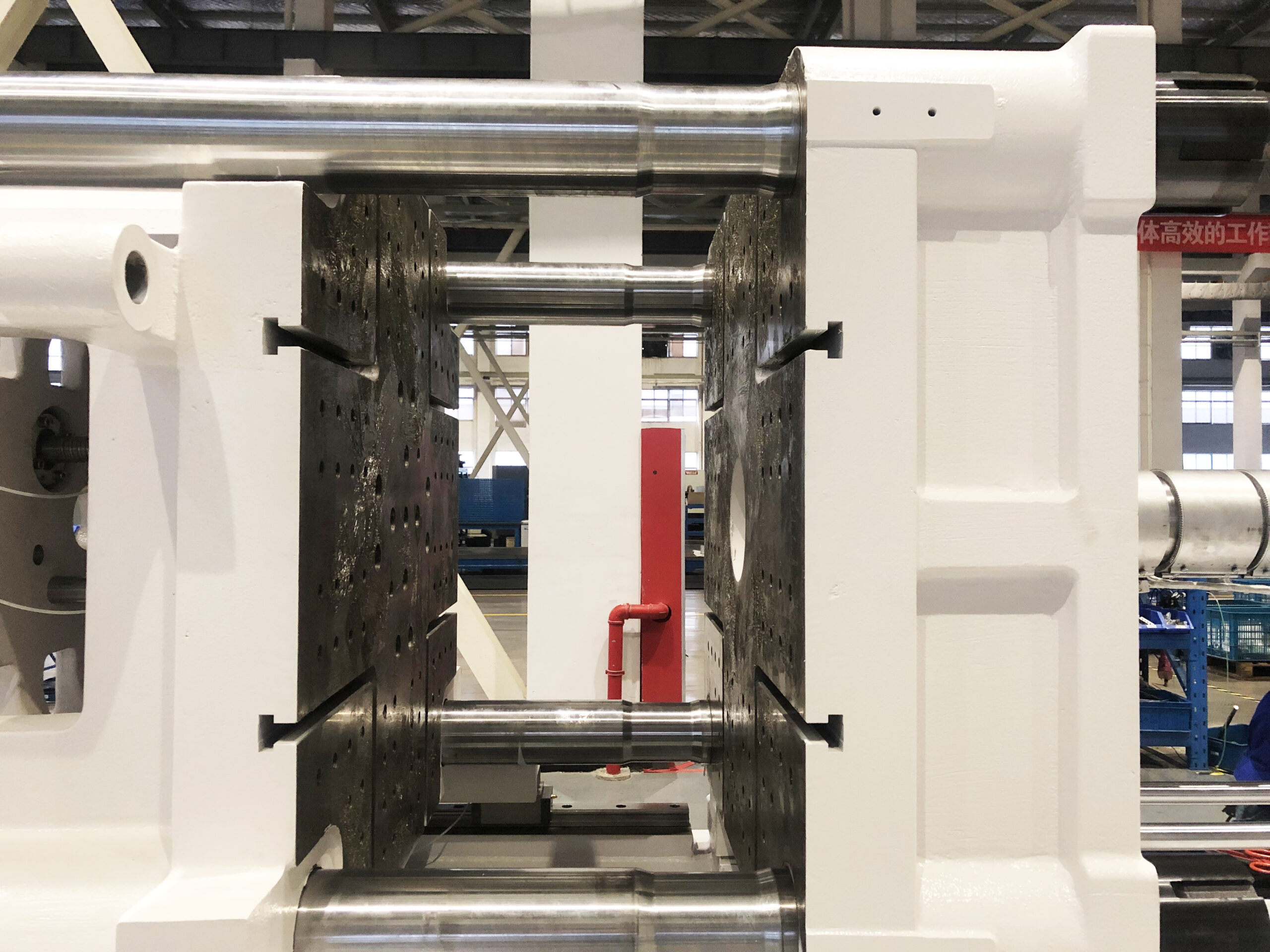

• High rigid toggle structure with 5 pins and self-lock, fast response speed, lead to smooth mold open/close, structure self-lock after high-pressure clamping, lengthen the service life of clamping ball screw and mold.

• T-slot & screw fixation platen embedded mold locating ring design, high-standard clamping system reduces mold loss and makes more easy mold installation.

• Zero-resistance clamping injection guider structure, heavy loaded guider device supported by linear track, better wear resistance, lower friction and more smooth operation. Optimize mold structure, tie bar no touch with moving platen, no lubrication. The system has high rigidity and strength, guarantee the accuracy of platen parallel excellently.

• Top responsibility servo motor and high torque ball screw is key element, origin Japan technology to keep advantage leading in the word, precise for mold movement.

•Fast and smooth mold movement, high torque, less resistance. Clamping servo motor connects ball screw, flexible operation and simply maintenance. High-quailty belt,warranty 10 years; superior rotating wheel, low inertia.

KEY Configuration :

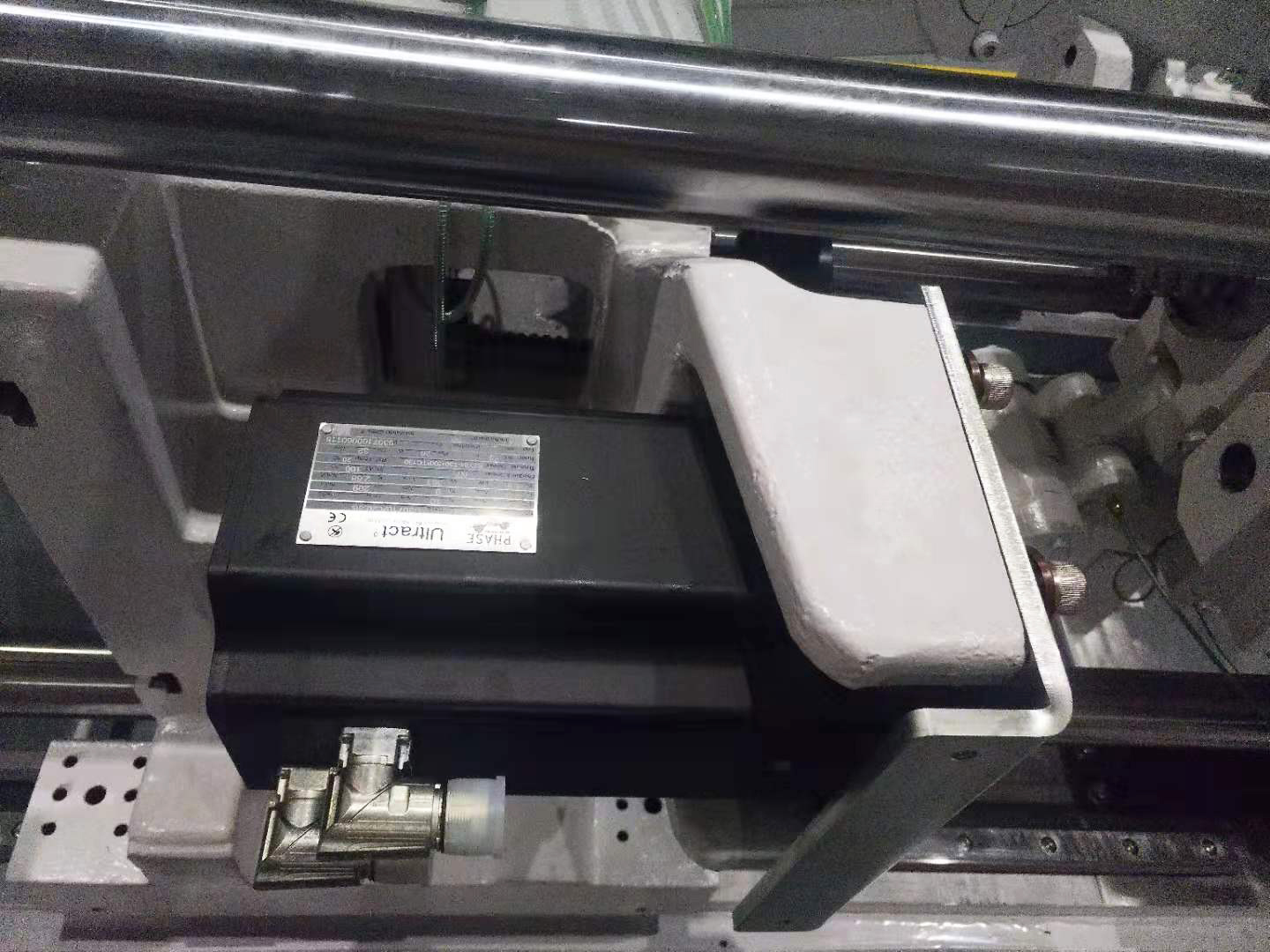

1) Servo: PHASE

2) System : KEBA

3) Gear Motor : SUMITOMO

4) Lubrications system : LUBE

5) Ball Screw : NTN or NSK

6) Synchronous belt : MITSUBOSH

Technical Advantages:Tec Base on Japan.

HighQuality >High Efficiency >High Precision >Energy-Saving

Gurantee: 2-3 Year

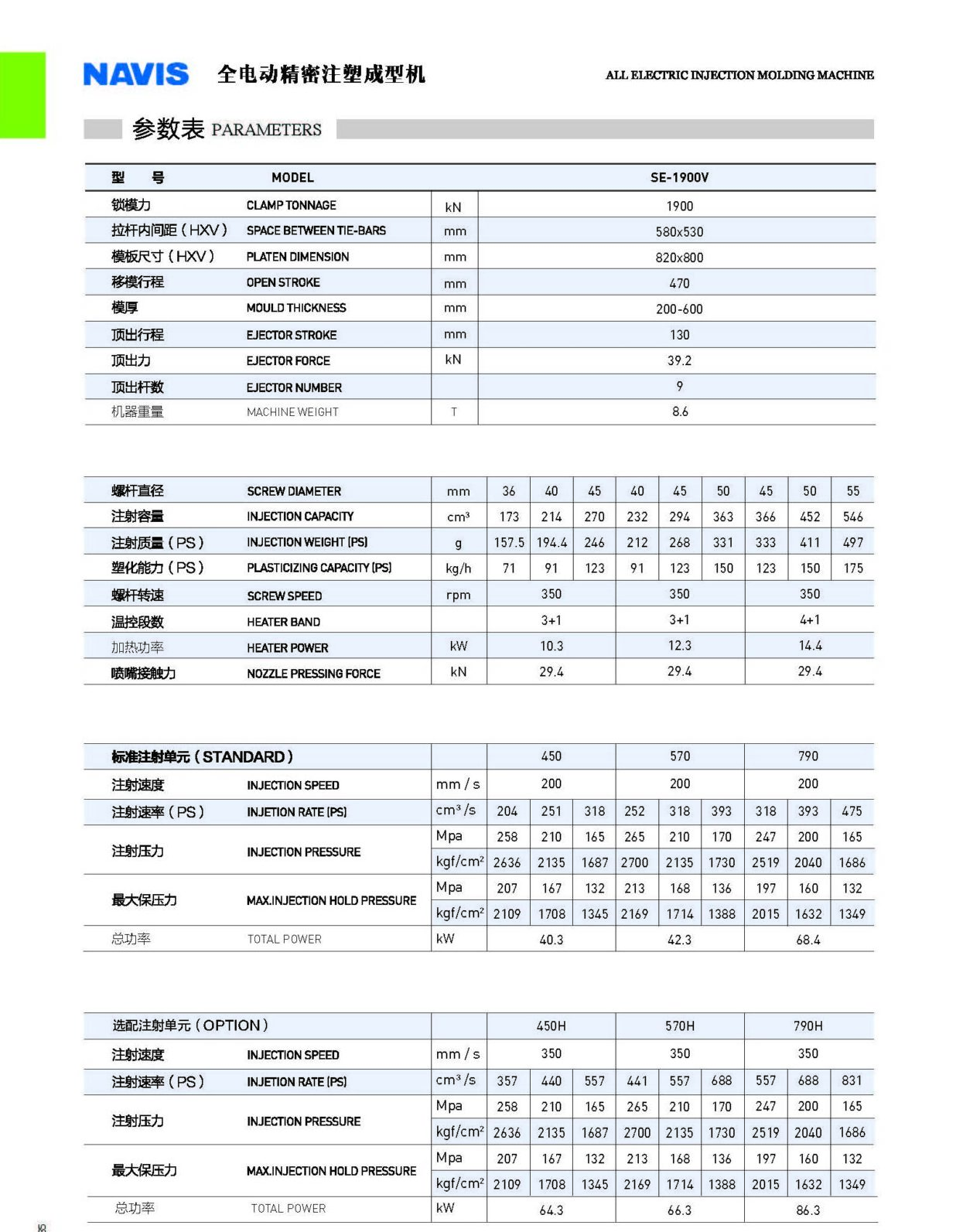

Specs

Please Click The Below Quick Links,Find Out Suitable Machine Model

Cases

Case for Medical Sector

190 Ton All electric injection moulding machine for medical product Pipette Tip

190 Ton Injection molding for Electronic Sector: Light Pipel

190 Ton Injection molding for Digital display board of Electric pen

190 Ton full electric Injection moulding machine for BEARING WASHER

190Ton Electric molding machine for Piston cavity32 cycle time 20s material PP

Other Cases

Machine Disptach

Comments