High Speed Blow Injection Molding Machine

VOL:1.5L, 2L ; CY:6000~9000 Pcs/h

Description

Benefits & Features

• Horizontal rotation transfer system make the construction and maintance more easy, reduce cost of spare part change.

• Compact preform heating distance design for efficient heating and reduce energy consumption.

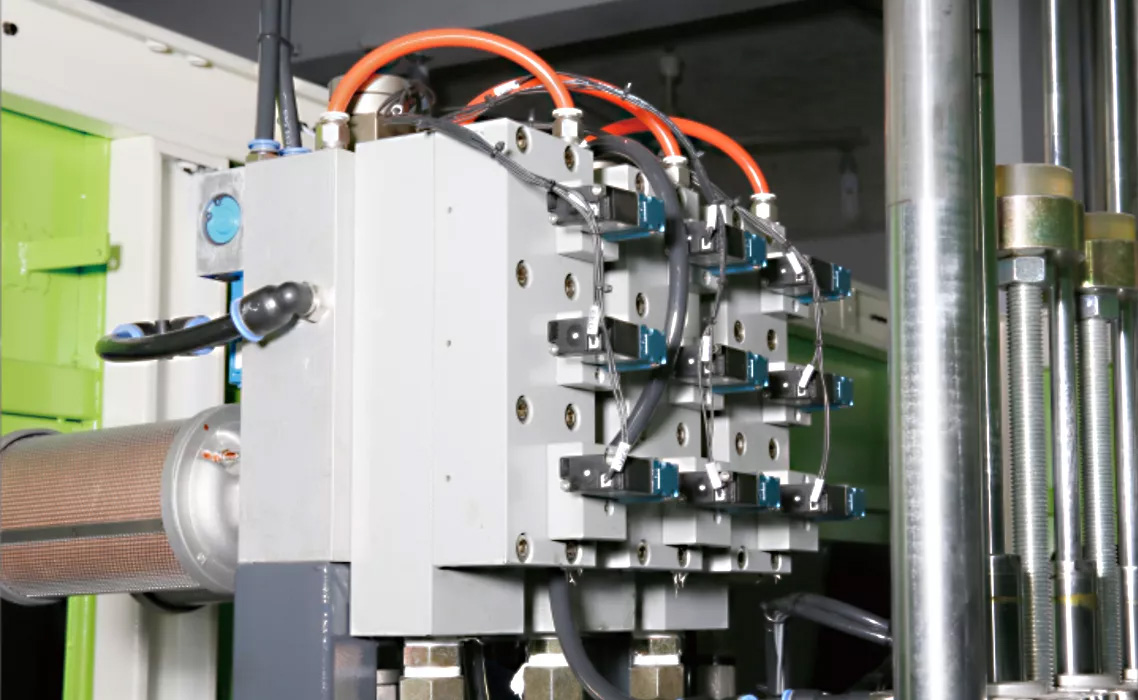

• Using hard claw to catch the preform and bottle, resistance to wear with long life.

• Mould closing adopts CAM linkage, no chain plate pin shaft make it small volume and long lift.

• stainless steel pipe make the air more clean without pollution.

• Servo motor drive system with synchronized base blow mould for fast response operation, precision blowing valve for high output. 7.slip for bottle mould make the installation more easy.

• Touch-panel control system for simple operation with 9 inch LCD screen.

• Compact preform heating distance design for efficient heating and reduce energy consumption.

• Using hard claw to catch the preform and bottle, resistance to wear with long life.

• Mould closing adopts CAM linkage, no chain plate pin shaft make it small volume and long lift.

• stainless steel pipe make the air more clean without pollution.

• Servo motor drive system with synchronized base blow mould for fast response operation, precision blowing valve for high output. 7.slip for bottle mould make the installation more easy.

• Touch-panel control system for simple operation with 9 inch LCD screen.