Extrusion Blow Molding Machine D Tie Bar Series

D series machine is standard type. Double station, tie-bar clamping system. Double proportional valve controls flow and pressure. Operator friendly access, enengy saving, automatic lubrication system, easy maintenance, well-known components of high quality, stable running, easy to collect flash. Excellent choice for economical equipment. From one layerto five layer, with view-line, one diehead to six diehead , diehead coating with Titanium alloy or Chromium or Nitride chromium, servo motor, thickness controller, filter screen device, conveyor;leak tester and auxiliary machineries are optional.

Description

Features

Benefits

- EXTRUSION DIE HEAD:HIGHLY EXPERIENCED MULTI-CAVITY AND MULTI-LAYER TECHNOLOGY

Adopting with latest die head design, SANTSAI focuses on providing high quality and high precision self-manufactured extrusion die heads for customers.

Adopting with latest die head design, SANTSAI focuses on providing high quality and high precision self-manufactured extrusion die heads for customers.

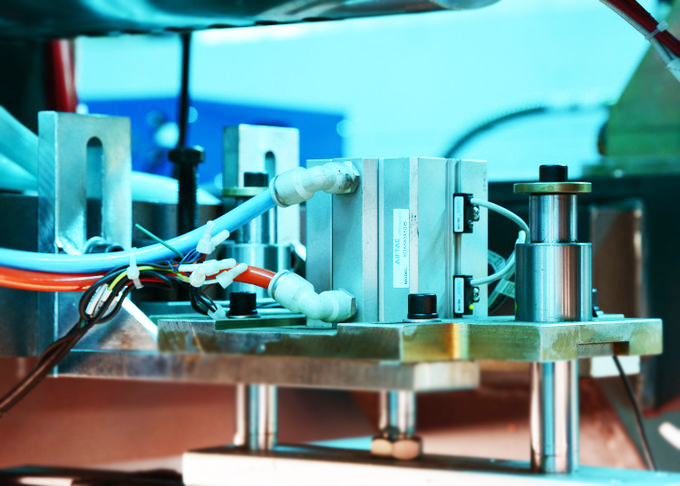

- CONTROL SYSTEM:HIGHLY OPTIMIZED USER-FRIENDLY CONTROL TECHNOLOGY

All SANTSAI machines is equipped in standard with TECHMATION control system or optional with B&R control system. MOOG Parison Control is also optional based on different requirements.

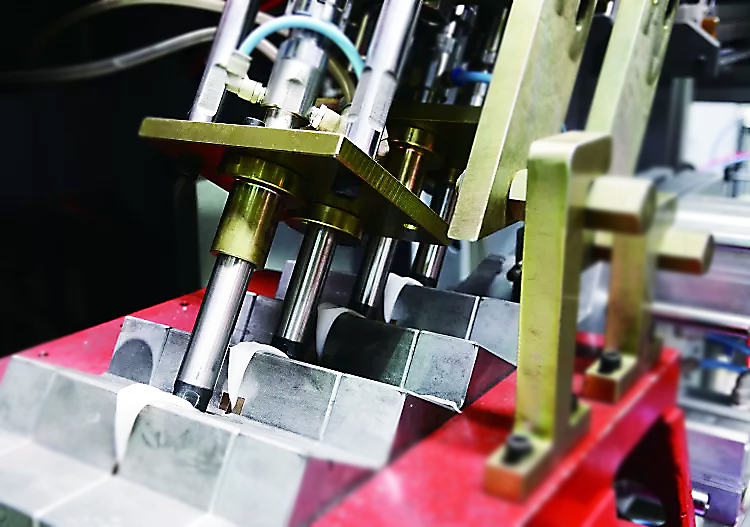

- CLAMPING SYSTEM:HIGHLY DEVELOPED TIE BAR DESIGN

MP-D Tie-bar series employs direct-acting clamping system transferring the forces directly to the middle of the back platen and converting the same force to the front by tie bars and alignment rod. This tie-bar design offers quick mould change and convenient scrap collection.

- EXTRUSION UNIT:HIGHLY BALANCED EXTRUDER DESIGN

ALL SANTSAI machines adopt with variable frequency motor drive, high-efficiency screw and barrel design, close-loop temperature control and reliable, low noised gearbox.

- POST MOULDING PROCESSES AND FINISHING :FULLY AUTOMATIC PRODUCTION PLAN

SANTSAI professionally provide fully automatic production plan for customers including auto-deflashing, leakage testing, robotic arms and so on. All processes can be finished in line.

Standard Features:

- Auto Lubrication

- Water Cooled Modular Blow Pin

- Hot Wire Cutting

- Positioning Hole For Quick Mold Change

- Adjustable Die head

- Linear Transducer

- FRL(Filter Regulator Lubricator) for Pneumatic

- Proportional Hydraulic System fro better control

- Swing and Adjustable Extrusion Platform

OPTIONAL FUNCTION

- COLD CUTTER

- DEFLESHING SYSTEM(MACHINE SYSTEM+STEEL BACK PLATEN AND PNEUATIC CYLINDER)

- HYDRAULIC DEFLESHING SYSTEM

- BOTTLE ROTATION TOP CUT OFFLINE

- BLADE NECK ROTATION CUTTING ONLINE INSTALLED/OFF LINE SEPARATE

- HYDRAULIC FILTER

- MECHANICAL FILTER

- LEAK TEST MC ON/OFF LINE

- ROBOT TAKE OUT

- IML(IN MOULD LABELING SYSTEM)

- 2 YEAR SPARE PARTS WARRANTY

- SCRAP MATERIAL CONVENYOR

- BOTTLE CONVENYOR AROUND THE MACHINE OR CUSTOM DESIGN

- POST COOLING SYSTEM

- SIDE WATER REGUAR 12IN-12OUT WITH FLOW CONTROL

- PARISON CONTROL SYSTEM MOOG 100PTS

- SPECIAL SCREW AND BARREL FOR SPECIAL MATERIAL

- SPECIAL PROGRA FOR SPECIAL PRODUCTS AND MOULD DESIGN

- LOADING DEVICE,MASTER BATH MIXING DEVICE

Specs

STS Machine Model |

Unit |

55D |

70D |

80D |

| General Specification | ||||

| Capacity/Article Size | L | Up to 2 | Up to 5 | Up to 10 |

| No.of Dies | no. | 1,2,3,4 | 1,2,3,4,6 | 1,2,3,4,6,8 |

| Machine Dimension (L*W*H) | m | 2.87*2.14*2.28 | 3.6*2.2*2.36 | 4*2.3*2.5 |

| Total Weight | T | 3.5 | 5.5 | 8.2 |

| Clamping System | ||||

| Clamping Force | kN | 30 | 75 | 150 |

| Mould Dimensions(W*H) | mm | 360*300 | 430*470 | 520*460 |

| Platen Opening Stroke | mm | 120-350 | 180-480 | 220-620 |

| Toggle Stroke | mm | 230 | 300 | 400 |

| Extrusion Unit with Inverter Drive | ||||

| Scew Diameter | mm | 55 | 70 | 80 |

| Length/Diameter Ratio | L/D | 24 | 24 | 24 |

| Plasticizing Capacity(HDPE) | Kqh | 45 | 70 | 90 |

| Scew Heating Zone | no. | 3 | 3 | 4 |

| Scew Heating Power | kW | 10.1 | 14.1 | 19.6 |

| Fan Power | kW | 0.18 | 0.18 | 0.22 |

| Extruder Driving Power | kW | 11 | 18.5 | 30 |

| Extrusion Die Head | ||||

| Die Head Heating Zone | no. | 2 | 2 | 2 |

| Power of Die heating | kW | 4.2 | 6.5 | 13.5 |

| Energy Consumption | ||||

| Total Connected Load | kW | 33.34 | 49.14 | 74.98 |

| Power Of Electric Motor | kW | 7.5 | 9.5 | 11 |

| Air Pressure | Mpa | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 |

| Average Power Consumption | kW | 23.9 | 28 | 35 |

| Average Compression Air Consumption | m^3/min | 0.8-1 | 1.2 | 1.5 |

| Average Cooling Water Consumption | L/min | 30 | 40 | 40 |

Cases

Application Category

Plastic Blow Molding machine for HDPE bottle

Plastic Blow Molding machine for HDPE bottle

Plastic Blow Molding machine Reagent bottle with cavity 6 and automatic runner cutter

Plastic Blow Moluding machine for bottle

Plastic Blow Moluding machine for bottle

Injection Blow Molding Machine for house bottle with automatic labling

Blow molding machine for HDPE Shampoo bottle

Comments