4 Axis for 700~1200Ton

Labor saving, stable cycle, high safety, suitable for all types of horizontal injection molding machines of 60-4000 tons, used in the removal of finished products with higher appearance and precision

Description

Benefits & Features

Suitable for800-1200T injection molding machine

● The modular production and high-strength aluminum alloy precision casting is used for the overall machine.

● The high-strength aluminum extrusion profiles are used for CNC machine-shaping arm to achieve the high speed, high rigidity, lower vibration, abrasion resistance

● More long service life with the help of the precision linear sliding rails.

● Applicable for various products with good universality.

Standard Function |

|

| Vacuum confirmation circuit | While part need to use suction cup by vacuum, one set for standard,(Extra one need cost) |

| Mold area movement | Robot can do horizontal movement freely in the mold area to take out the product with barb or others. |

| Release or grip in mold area | Can release part or runner in mold area after grip the runner or absorb the part. |

| Outside mold area stand-by | Robot can stand-by outside mold(outside the safety door) when robot end arm meets those mold obstructions. |

| Language selection | Language can be changed between Chinese and English. |

| Standard program sequences | Use with standard program sequence. |

| Conveyor interface | Control conveyor to run or stop. |

| Free edit mode | Freely programmable teach programs for flexible applications. |

| Out mold descent slow speed | Used to slow the speed when the product is taken out mold, to avoid accidents. |

| Grip pressure | You can have a precision adjustment of the grip pressure to ensure the products can be take out stability without any damage. |

| Quick exhaust | The exhaust valve at the air supply system is added to exhaust air quickly to release air pressure, it is used when a new mold will be changes to reset all actions, with this function an operator don’t need to do a improper operation(Remove the air supply system connector to exhaust) to avoid any damage. |

| Mid-Mold induction | Just after the mid-mold in right position signal confirmed, the robot second arm(assistant arm) will move down into mold area. |

| Optional Function | |

| Air nipper circuit | While cutting runner, use this function.(Scissor device is optional) |

Specs

Model |

Unit |

KAW-1600-F |

KAW-1800-F |

Arm type |

Telescopic type |

||

Vertical stroke |

mm |

1600 |

1800 |

Crosswise stroke |

mm |

1800 |

2000 |

Swing stroke |

mm |

2800 |

3200 |

Drive system |

X Y Z A Servo motor |

||

Swing angel |

degree |

270 |

270 |

Max loading(with tool) |

kg |

10 |

15 |

Min take time |

sec |

4 |

4 |

Dry cycle time |

sec |

9 |

12 |

Working air pressure |

kgf/c㎡ |

5-7 |

5-7 |

Air consumption |

NL/cycle |

25 |

25 |

Power consumption |

KVA |

1.5 |

1.5 |

Power |

AC |

220V 50-60HZ |

220V 50-60HZ |

Net weight |

Kg |

600 |

700 |

Gross weight |

Kg |

650 |

750 |

Product size |

m |

2.80*1.80*1.90 |

3.20*2.00*2.10 |

Packing size |

m |

2.85*1.85*2.00 |

3.25*2.05*2.20 |

Applicable IMM model |

T |

700-900 |

1000-1200 |

*The parameters are for reference only, please contact your sales representative for details.

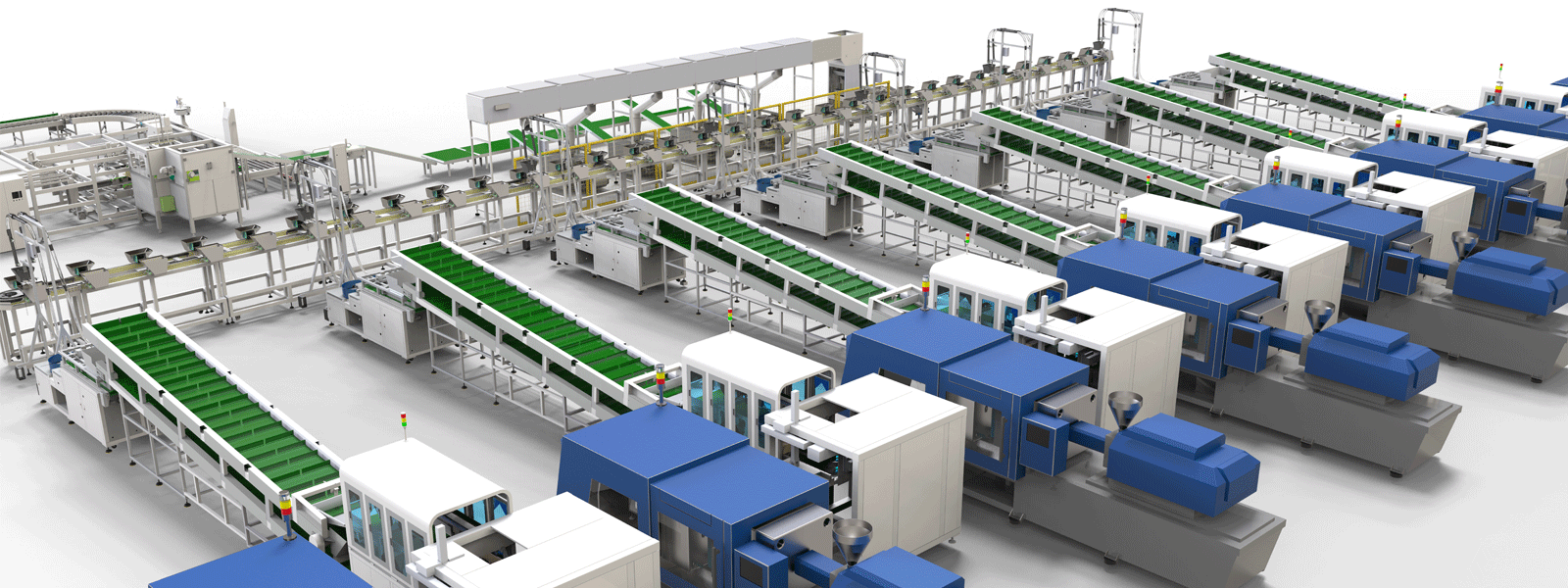

Cases

Application Category

Other Cases

Machine Disptach

Comments