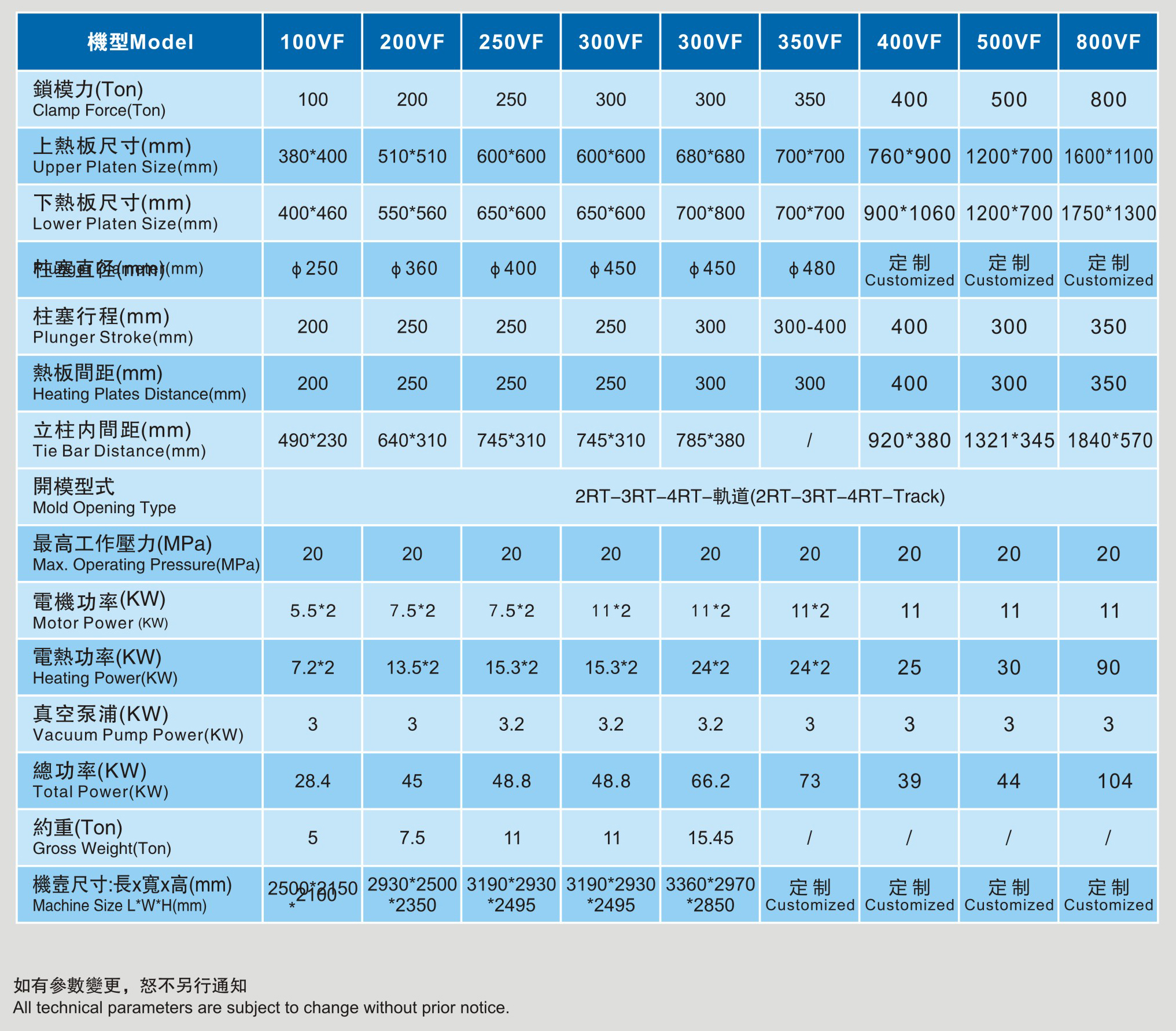

VACUUM COMPRESSION MOLDING MACHINE

Capacity:100Ton~800 Ton

Experience unparalleled efficiency with our Dual-Station Vacuum Compression Molding Machine, perfect for complex rubber and silicone components. Featuring independent oil circuits, high-quality German vacuum pumps, and uniform clamping force, this machine is ideal for automotive parts, electronic products, and more.

Description

Benefits & Features

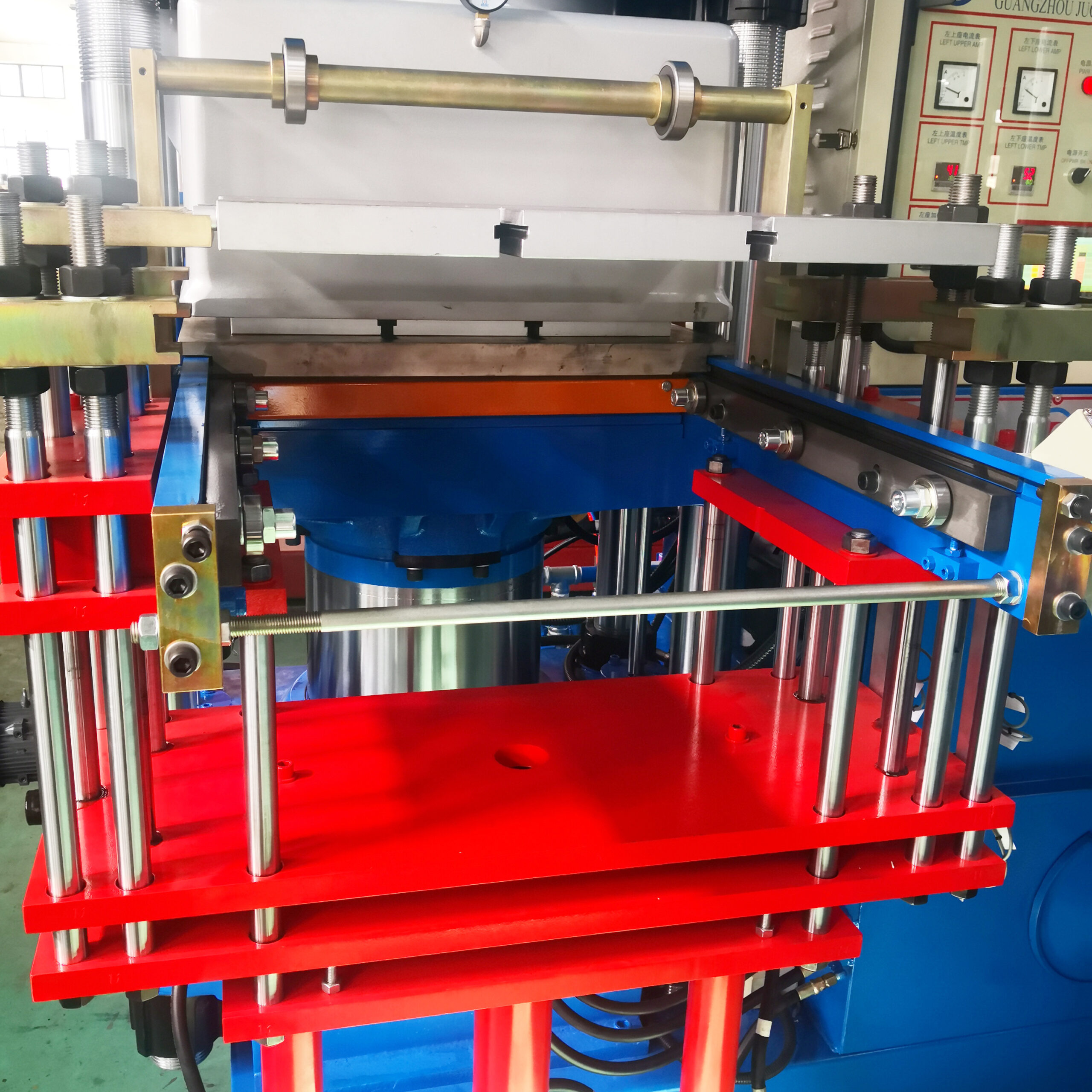

Our state-of-the-art Vacuum Compression Molding Machine is specifically engineered to handle complex structures and challenging exhaust processes in rubber and silicone spare parts manufacturing.

It is particularly effective for producing irregular rubber seals, automotive rubber components, conductive buttons, and sensitive electronic products.

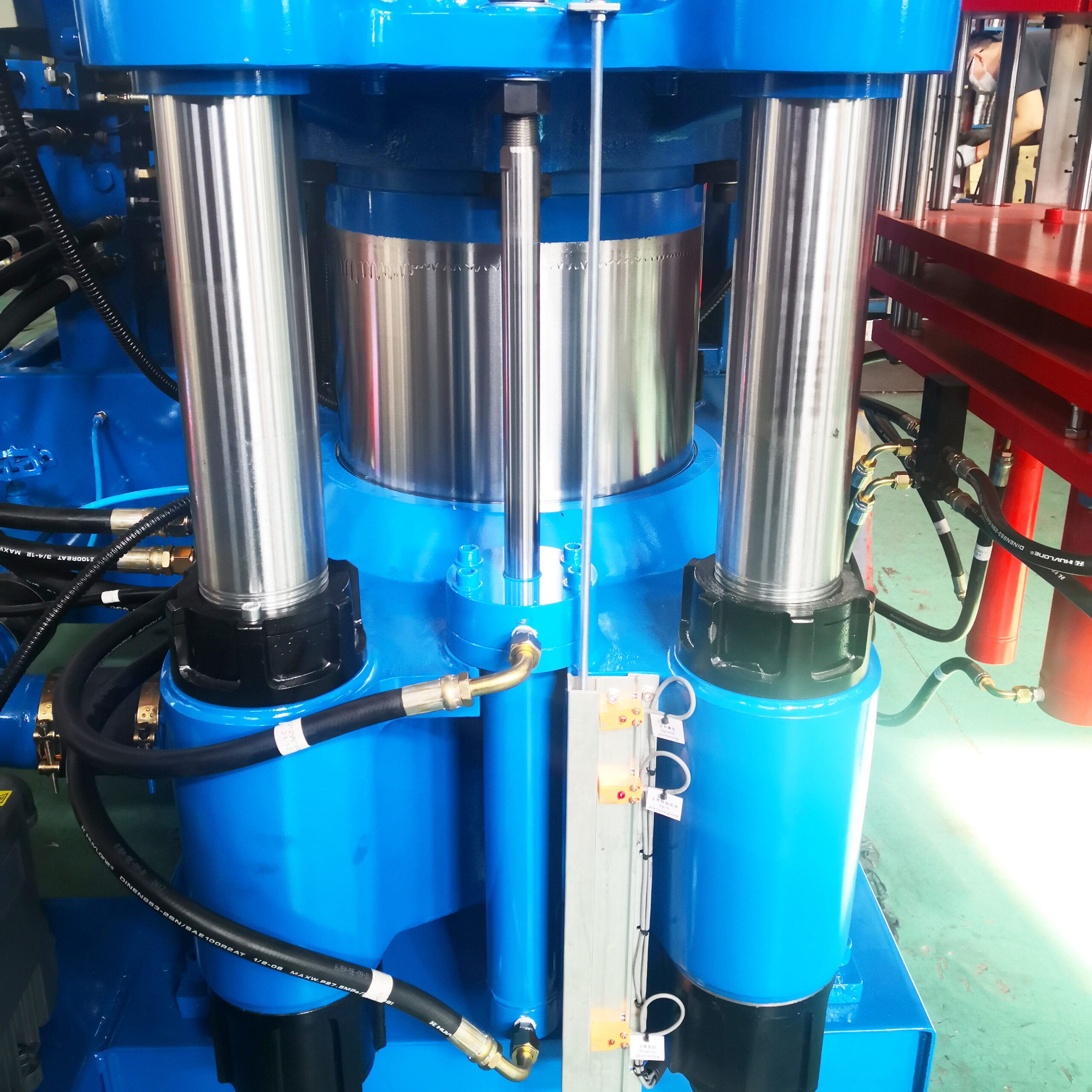

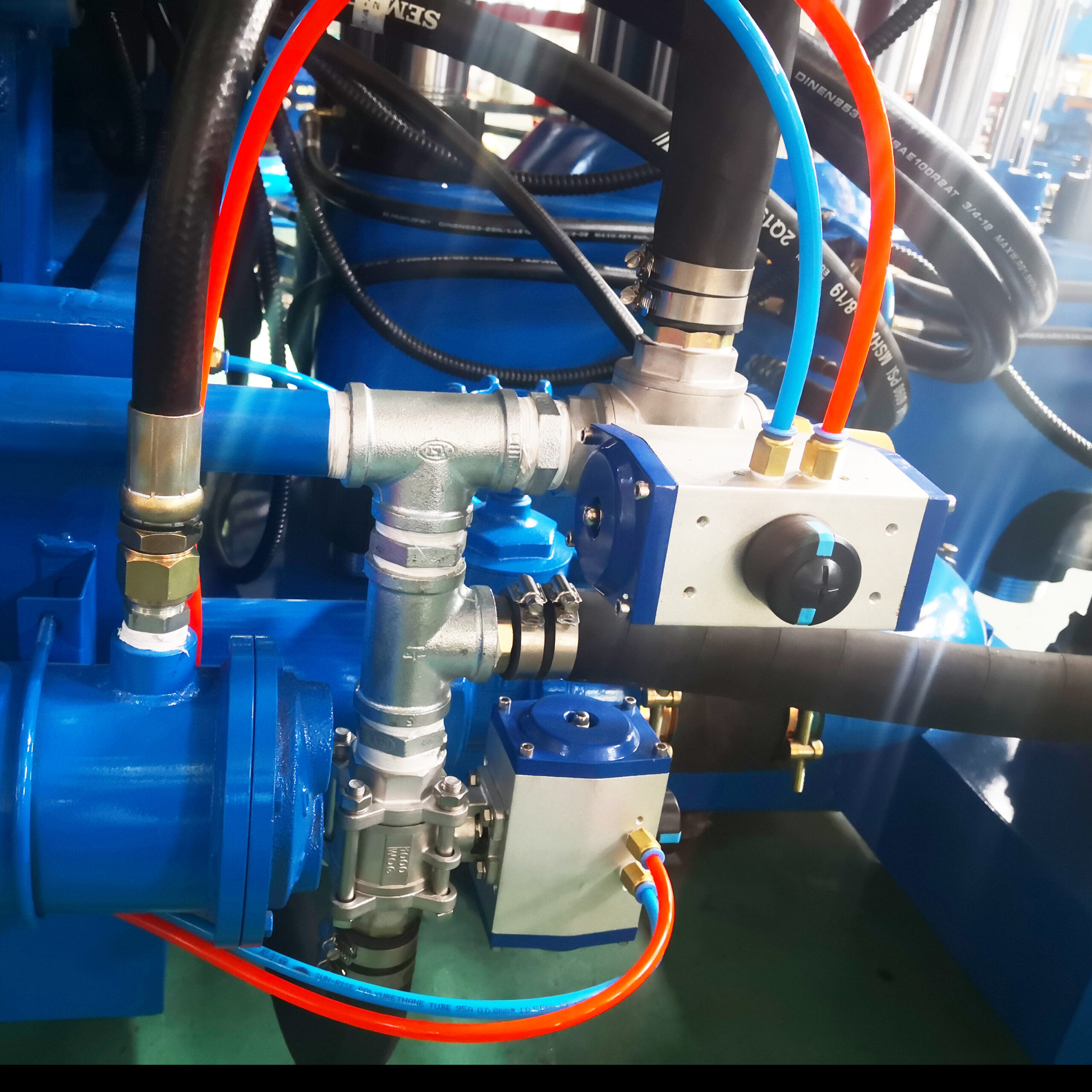

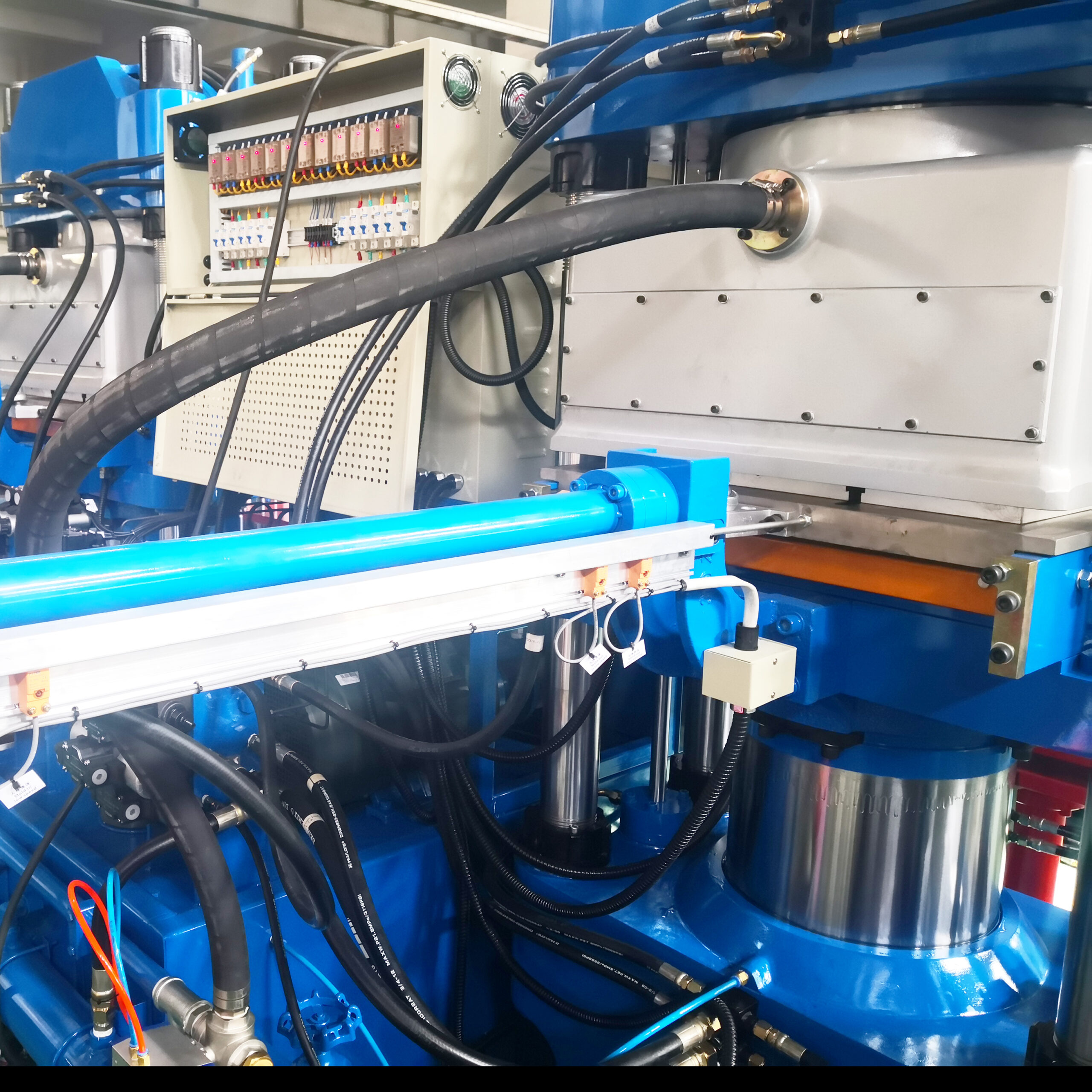

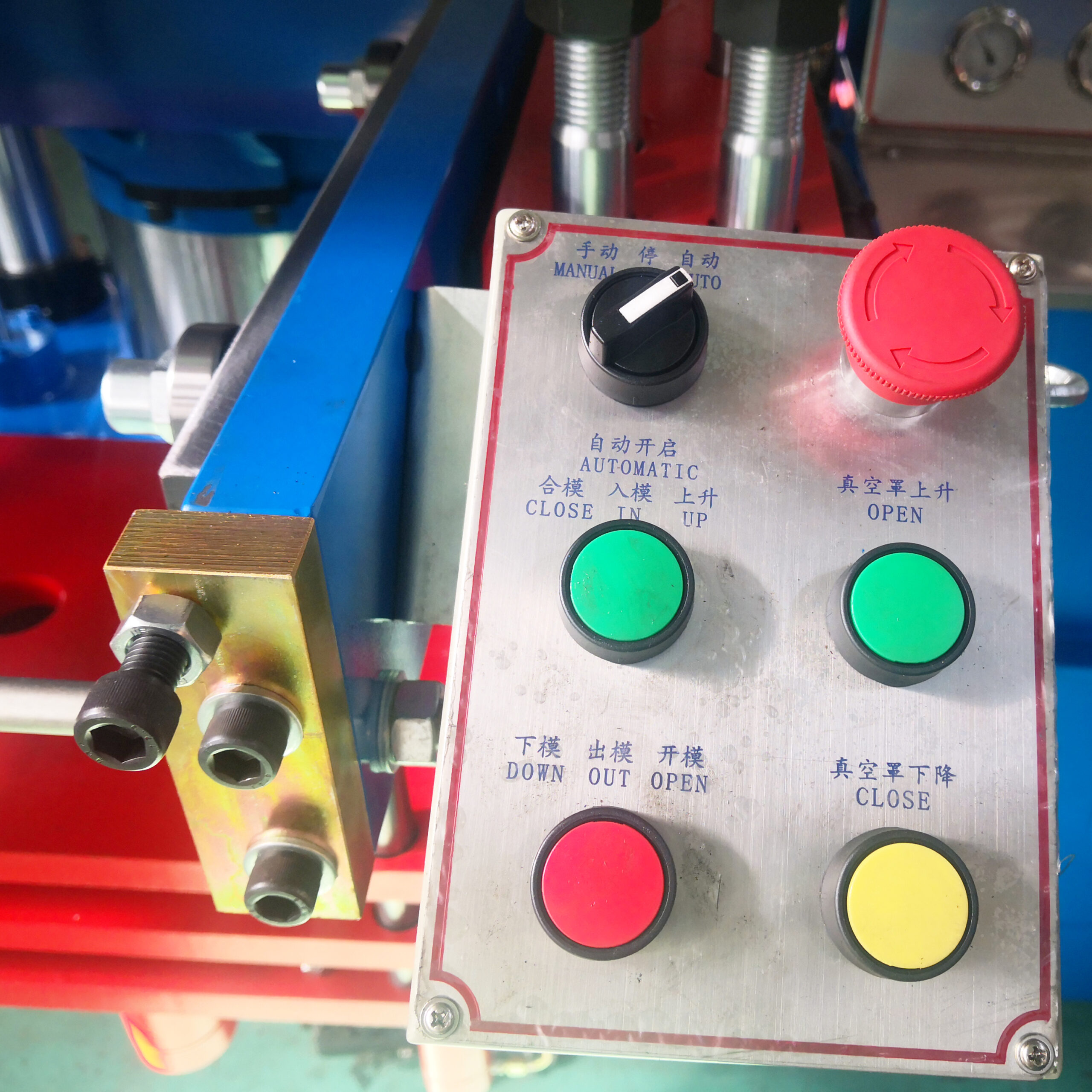

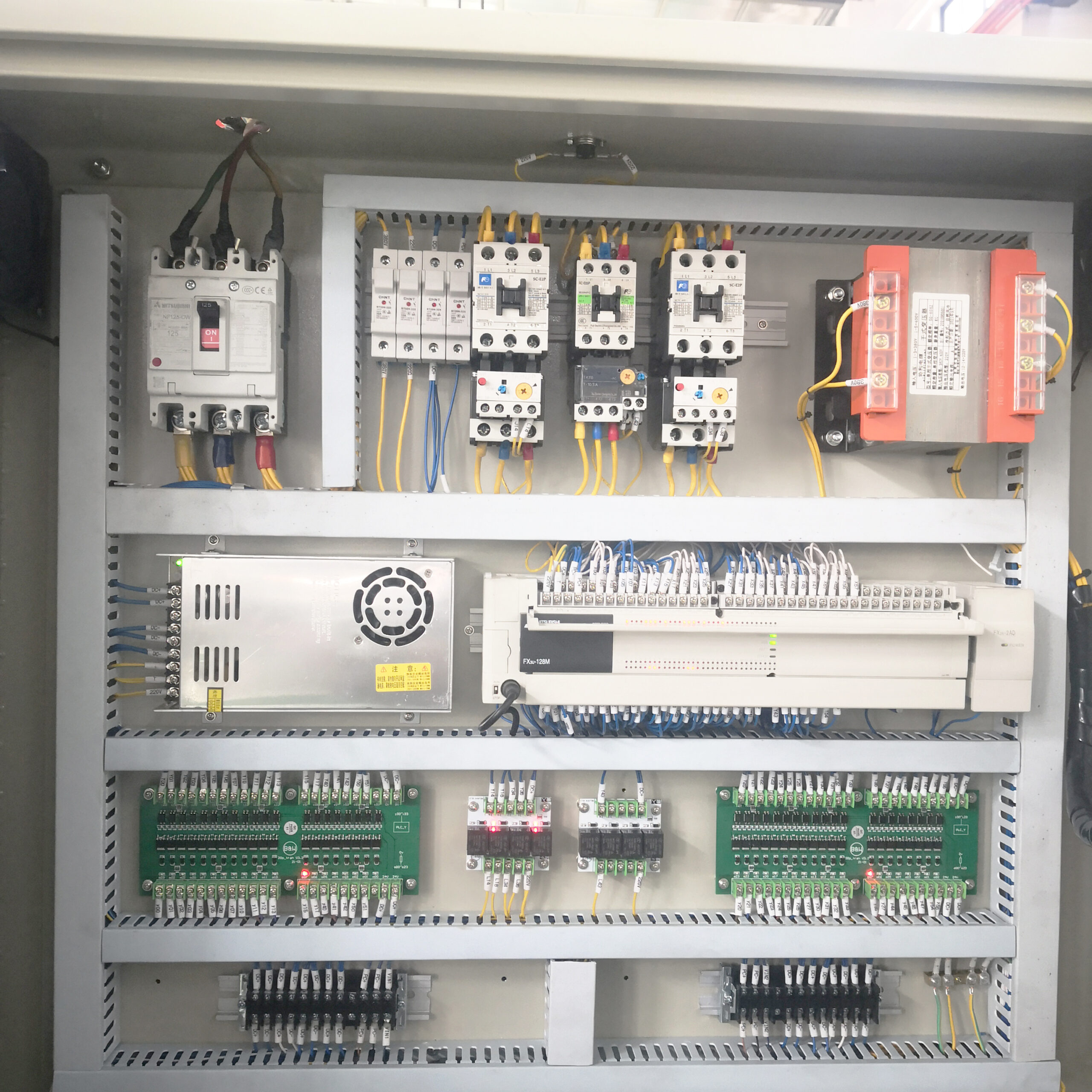

The machine boasts dual work stations that can operate independently or in tandem, each equipped with its own oil circuit, dual oil pumps, and motors.

This ensures efficient and reliable operation. The inclusion of a high-speed German vacuum pump guarantees rapid pumping speeds, enhancing overall productivity.

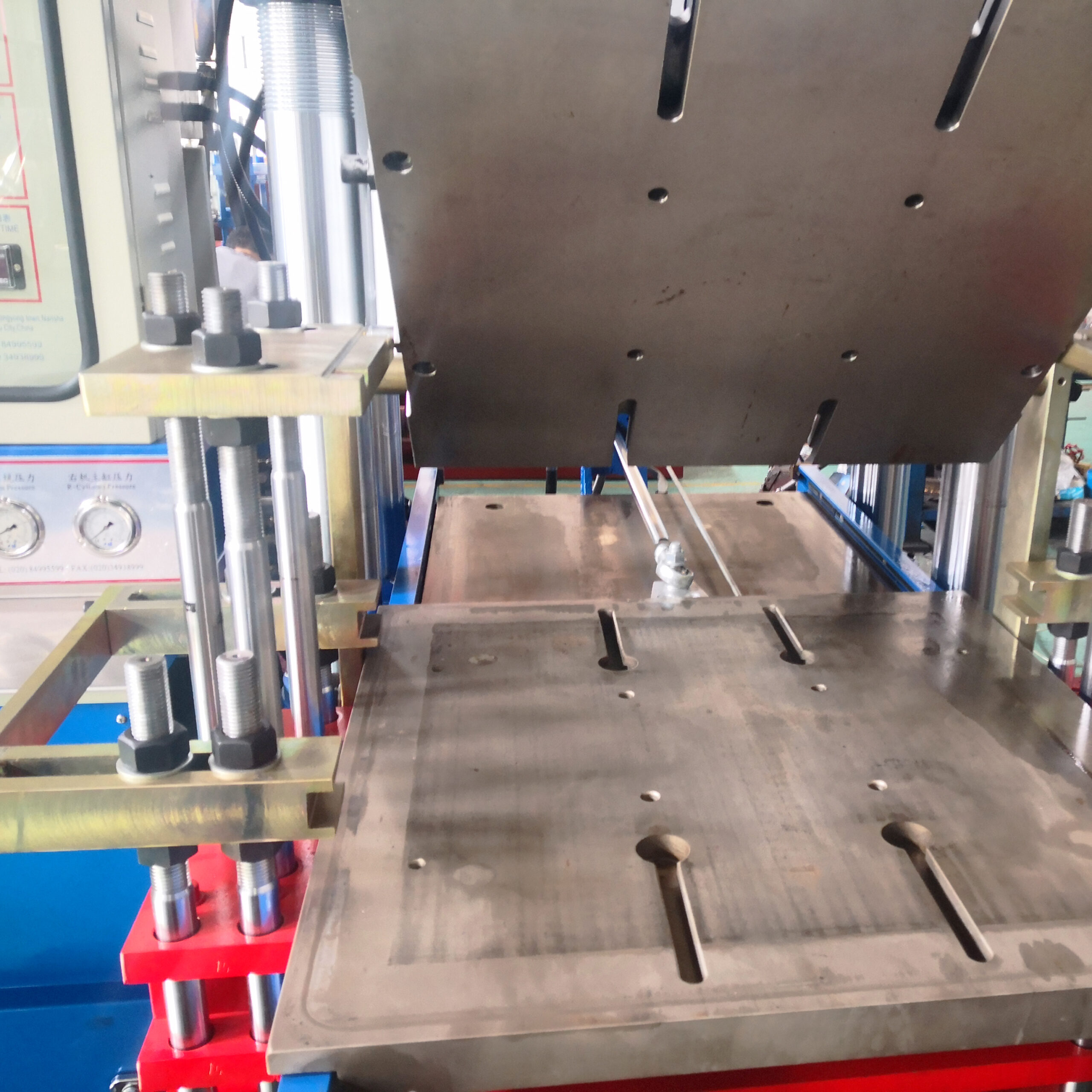

Additionally, the machine’s mechanical design plates ensure a more uniform clamping force, adaptable to various demolding structures. This machine represents a significant advancement in the molding industry, combining precision, efficiency, and versatility.

Main technical parameters

Specs

Cases

Application Category

Other Cases

Machine Disptach

Comments