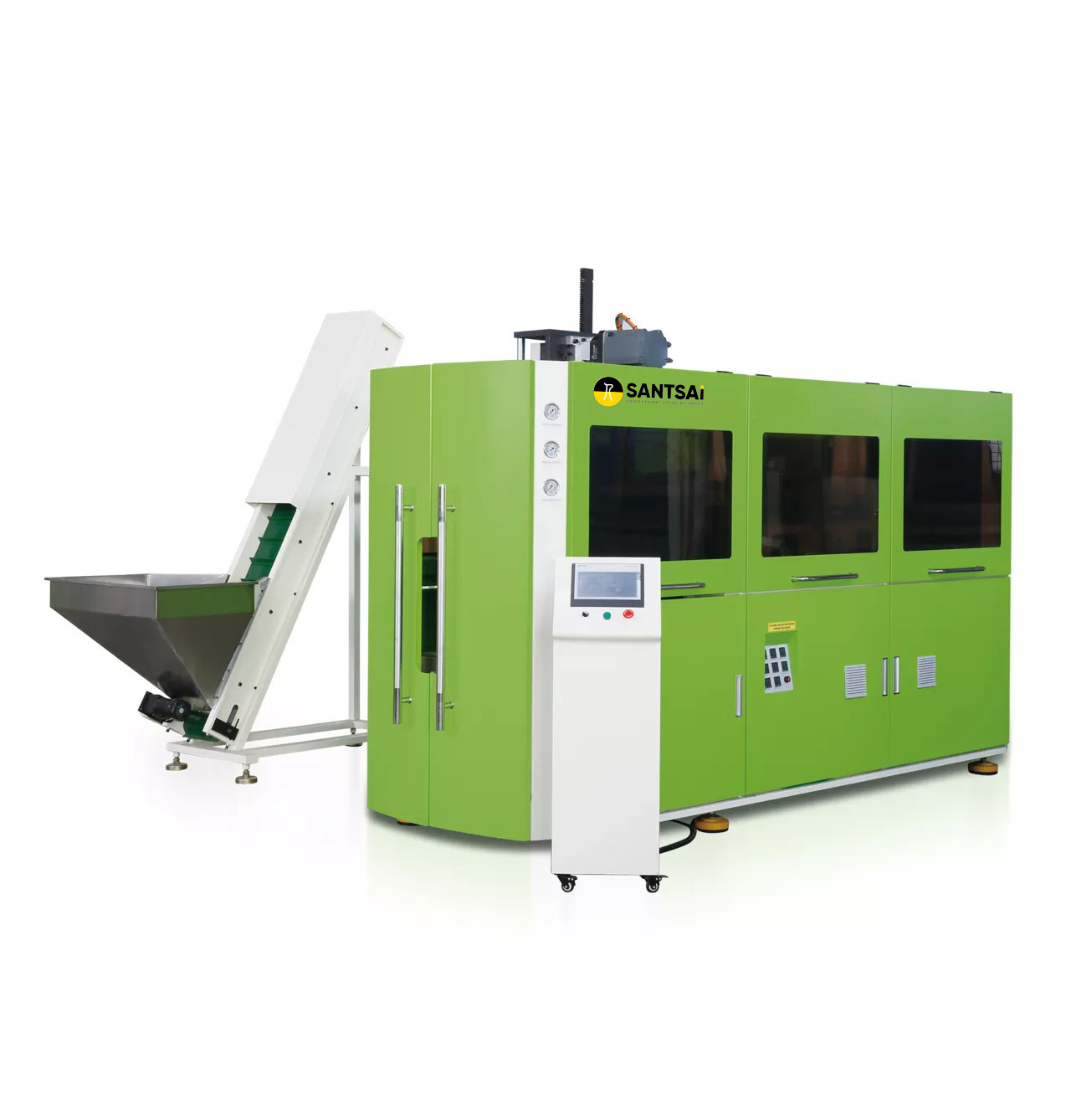

Two-step Multi functional Blow Injection Molding Machine

VOL:1.5L ; CY:2200 Pcs/h

Description

Benefits & Features

• Blowing 0.5-1.5 PET common bottle.

• Durable PLC micro computer controlling system controls time can be accurate to 0.01 seconds.

• Special recycling installation for high pressure air reduces the energy consumption.

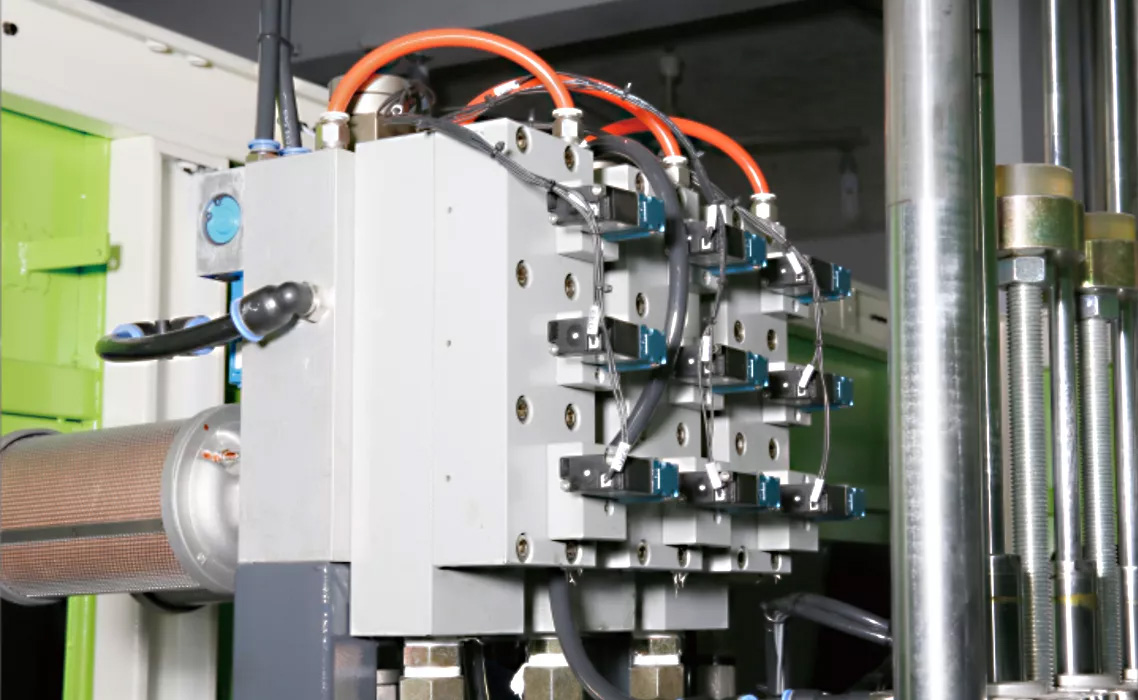

• The far-infrared heater uses a way of conversion self-rotating heating and the rail revolution makes the heating even, quick and reliable.

• Every heating lamp has independent temperature control device, to get ideal preform heating effect.

• Particular pre-heater design makes prefrom close while heating. Change space, shorten heating tunnel and reduce energy consumption according to the bottle size while blowing.

• simple installation and starting.

Specs

| Items | Unit | STSM-3 |

| Theoretical output | Pcs/hr | 2200 |

| Volume | L | 1.5 |

| Max. height | mm | 360 |

| Max. diameter | mm | 105 |

| Number of cavities | / | 3 |

| Mould plate dimension(LxH) | mm | 490×470 |

| Mould thickness | mm | 240 |

| Mould opening stroke | mm | 200 |

| Power | 220-380V/50-60Hz | |

| Total power | KW | 18 |

| Heating power | KW | 15 |

| Operation Pressure | Mpa | 0.8-1.0 |

| Action Air Consuming | m3/min | ≧1.0 |

| Blowing Pressure | Mpa | 2.6-3.0 |

| Blowing Air Consuming | m3/min | ≧1.6 |

| Main body dimension(LxWxH) | M | 2.05×1.45×2.5 |

| Main body weight | KG | 1500 |

| Preform Autoloader(LxWxH) | M | 1.7×2.1×2.2 |

| Preform Autoloader weight | KG | 200 |

| Bottle Conveyor(LxWxH) | M | 2.0×0.60×1.1 |

| Bottle Conveyor weight | KG | 80 |

Cases

Application Category

Other Cases

Machine Disptach

Comments