Two Color Injection

Capacity:170 Ton~530 Ton

Our Two Color Injection Molding Machine is an advanced solution engineered to produce high-quality two-color products with unparalleled efficiency and precision. This machine is specifically designed to meet the rigorous demands of various industries, offering innovative features that enhance productivity and product quality.

Description

Key Features

- Space-Saving Design: The second injection unit is set up on the plate, saving ground area and optimizing workspace for customers.

- 180-Degree Reciprocating Rotation Table: This feature on the movement plate allows for the setup of one mold to produce two different color products, enhancing versatility and productivity.

- Efficient Servo Gear Transmission: The servo gear transmission structure ensures high-speed rotation with stable and precise positioning, improving overall efficiency and product quality.

- Multi-Plate Design: Adaptable to various product requirements, this design can suit either a rotation table or a rotation shaft, providing flexibility for different production needs.

- Non-Contact Clamping: The turntable operates without touching the clamp, reducing faults caused by abrasion. This ensures precise positioning before the molds close, maintaining mold safety and extending the lifespan of the equipment.

Benefits

- High Precision and Stability: Advanced servo gear transmission and precise positioning mechanisms ensure consistent, high-quality production.

- Enhanced Efficiency: The 180-degree reciprocating rotation table and multi-plate design increase production speed and flexibility, accommodating various product requirements.

- Improved Safety and Longevity: Non-contact clamping during operation reduces wear and tear, ensuring the safety of the molds and the longevity of the machine.

- Space Optimization: The innovative design of the second injection unit saves valuable floor space, making it ideal for facilities with limited space.

- Versatile Application: Ideal for producing a wide range of two-color products, suitable for automotive, consumer goods, electronics, and other industries.

Applications

The Two Color Injection Molding Machine is perfect for industries that require high-quality, multi-color products. Its versatile design and advanced features make it suitable for:

- Automotive components

- Consumer electronics

- Medical devices

- Household products

- Packaging solutions

Technical Specifications

- Injection Unit Design: Second injection unit set up on the plate to save space

- Rotation Table: 180-degree reciprocating rotation on the movement plate

- Transmission: Efficient servo gear transmission for high-speed, stable, and precise rotation

- Design: Multi-plate configuration to suit various product requirements

- Operation: Non-contact clamping during turntable operation to reduce abrasion and ensure precise mold positioning

Customized services for specific product and Sector, Such as

Two Color Machine

C Type Machine

Glass Fiber

Bakelite Machine

Zipper Machine

Horizontal clamping & vertical injection machine

Umbrella machine etc.

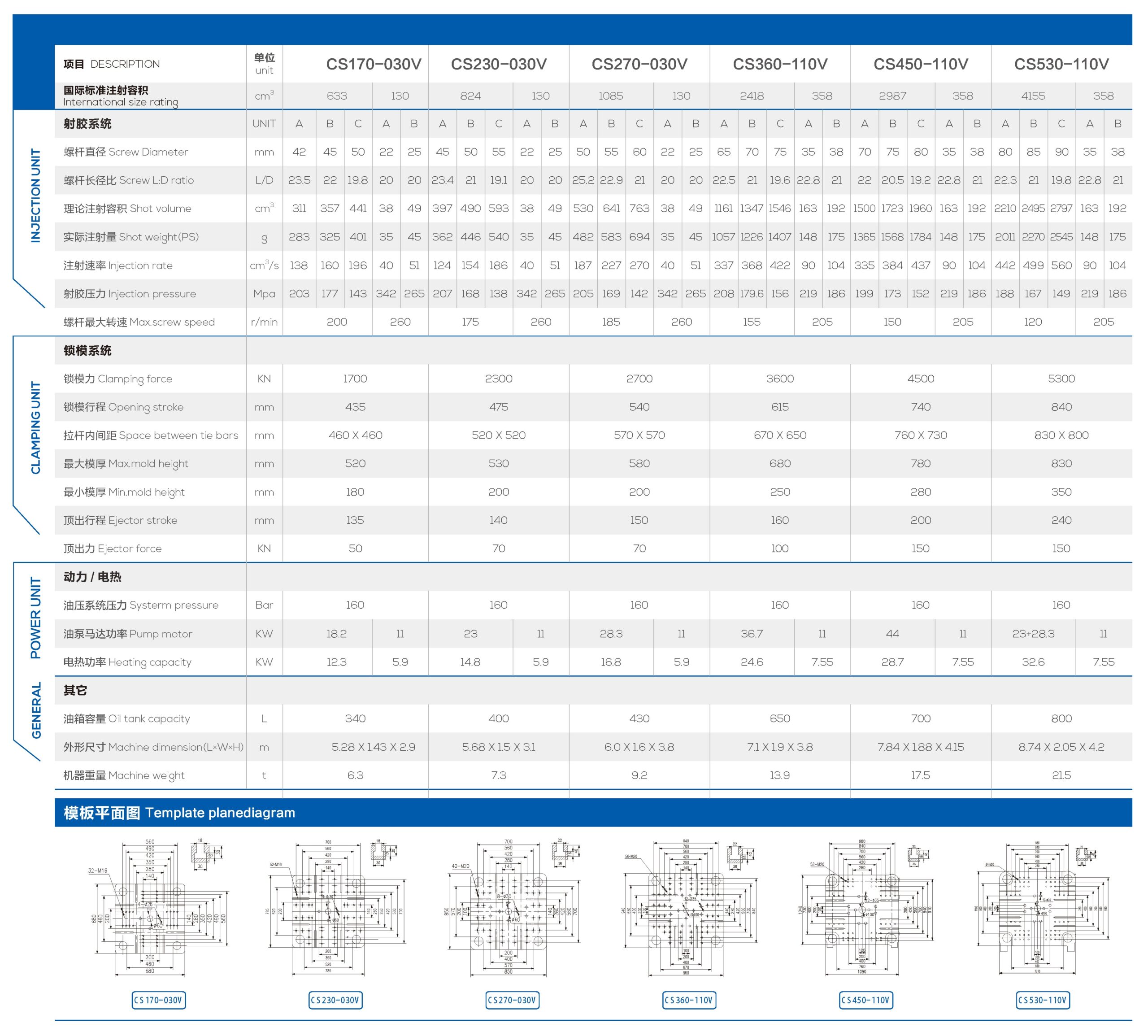

Specs

Cases

Application Category

The Two Color Injection Molding Machine is versatile and suitable for producing a wide range of multi-color products. It is particularly useful in the automotive industry for manufacturing complex, high-quality components. Additionally, it is ideal for use in the production of consumer goods, electronics, medical devices, and more.

Other Cases

Machine Disptach

Comments