Syringe Assembling Machine

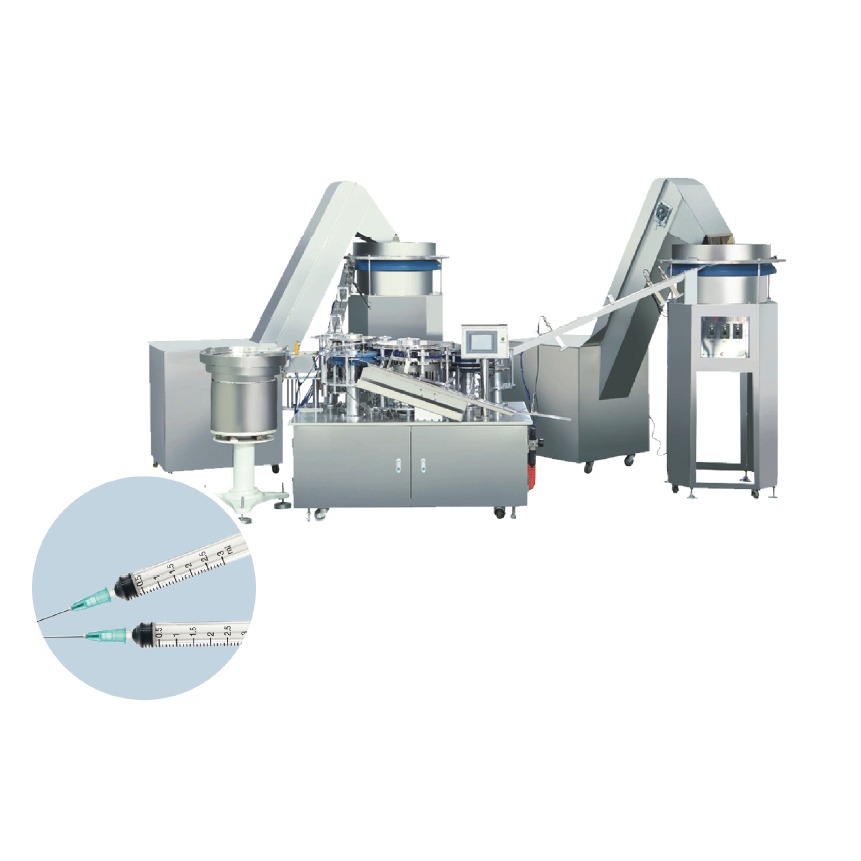

The Syringe Assembling Machine is designed to automate the assembly of syringes. It efficiently produces various types of syringes, such as luer slip and luer lock types. The machine features an LCD display to monitor and adjust the feeding speed, allowing for separate assembly speed adjustments and electronic counting. It operates with high efficiency, low power consumption, stable performance, and low noise, making it suitable for GMP workshops.

Description

The Syringe Assembling Machine is designed to automate the assembly of syringes. It efficiently produces various types of syringes, such as luer slip and luer lock types. The machine features an LCD display to monitor and adjust the feeding speed, allowing for separate assembly speed adjustments and electronic counting. It operates with high efficiency, low power consumption, stable performance, and low noise, making it suitable for GMP workshops.

Introducing the Syringe Assembling Machine: Efficiency and Precision in Syringe Production

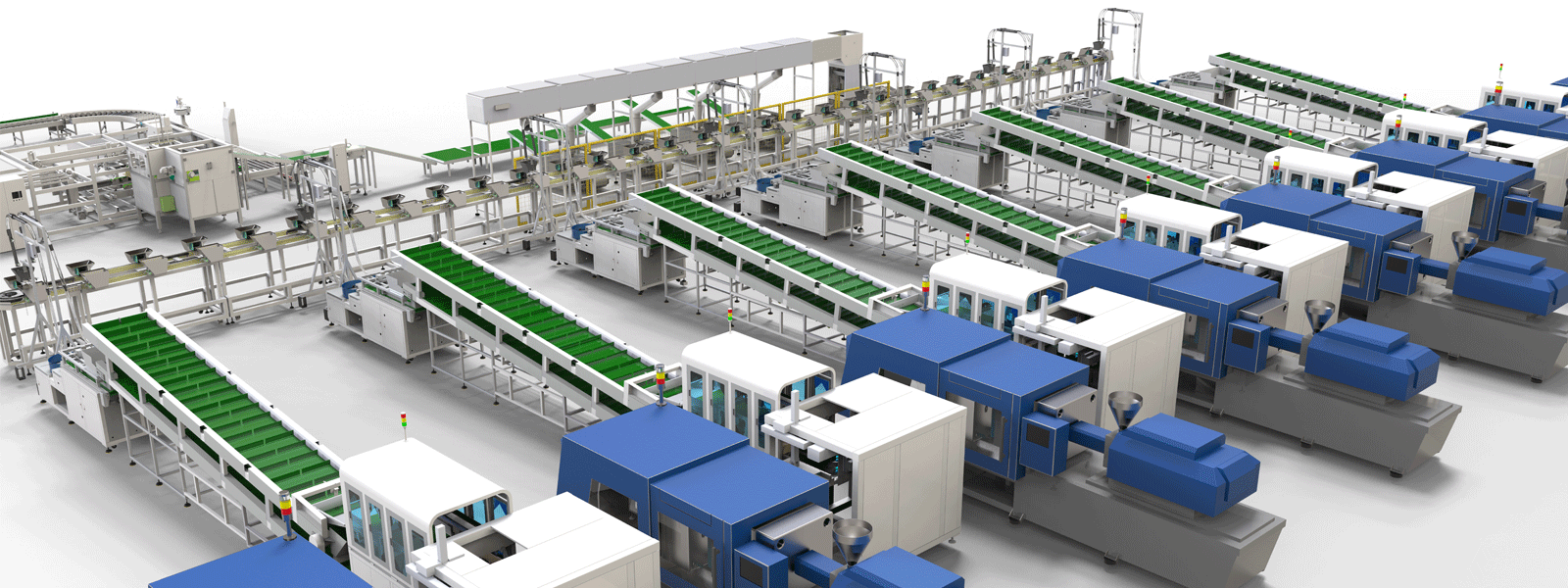

In the medical manufacturing industry, precision and efficiency are paramount. The Syringe Assembling Machine stands out as a state-of-the-art solution for automating the syringe assembly process. Capable of producing all types of syringes, including luer slip and luer lock types, this machine is a versatile addition to any production line.

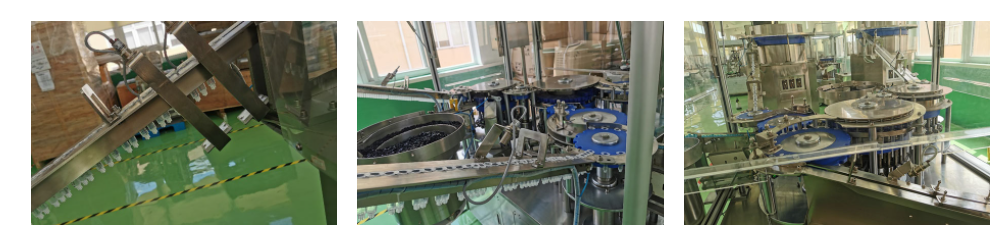

Equipped with an intuitive LCD display, the machine allows operators to easily monitor and adjust the feeding and assembly speeds. The electronic counting feature ensures accurate production tracking, while the low power consumption design supports cost-effective operations. Maintenance is straightforward, and the machine operates with minimal noise, providing a conducive working environment.

The Syringe Assembling Machine comprises a sophisticated feeding system and a precise assembly mechanism. The feeding system autonomously delivers the four syringe components—plunger, stopper, needle, and barrel—to the assembly mechanism. Using photoelectric sensors, the system can automatically regulate feeding based on the assembly mechanism’s status, ensuring seamless production flow.

The assembly mechanism completes three critical actions: assembling the plunger with the rubber stopper, attaching the barrel to the needle, and finally combining the plunger and stopper with the barrel and needle. This meticulous process guarantees the production of high-quality syringes ready for medical use.

Specs

Main Technical Parameters:

Model | ZZ-001IV |

| Applicable Specification | 2ml~50ml |

| Production Capacity | 150-250pcs/min |

| Overall Dimension | 4200*3000*2100mm |

| Weight | 1500kgs |

| Power Supply | AC220V/3KW |

| Compressed Air Flow | 0.3m³/min |

Main Configuration List

No. | Name | Brand | Remark |

1 | Frequency converter | Mitsubishi (Japan) | |

2 | Motor | Taizhou, China | |

3 | Reducer | Hangzhou, China | |

4 | Adjustable-speed motor | Mitsubishi (Japan) | |

5 | Control system | Single chip microcomputer | |

6 | Touch Screen | China | |

7 | CCD vision sensor system | KEYENCE (Japan) | |

8 | The housing material | SS 304, Plated metal | |

9 | Dust cover | Aluminum profile |

Note: Non-Standard Equipment cn be Customized according to the capacity of Injection Machine and requirements.

Comments