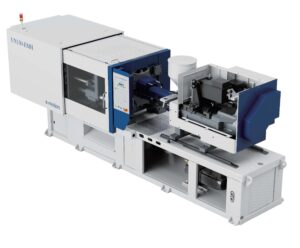

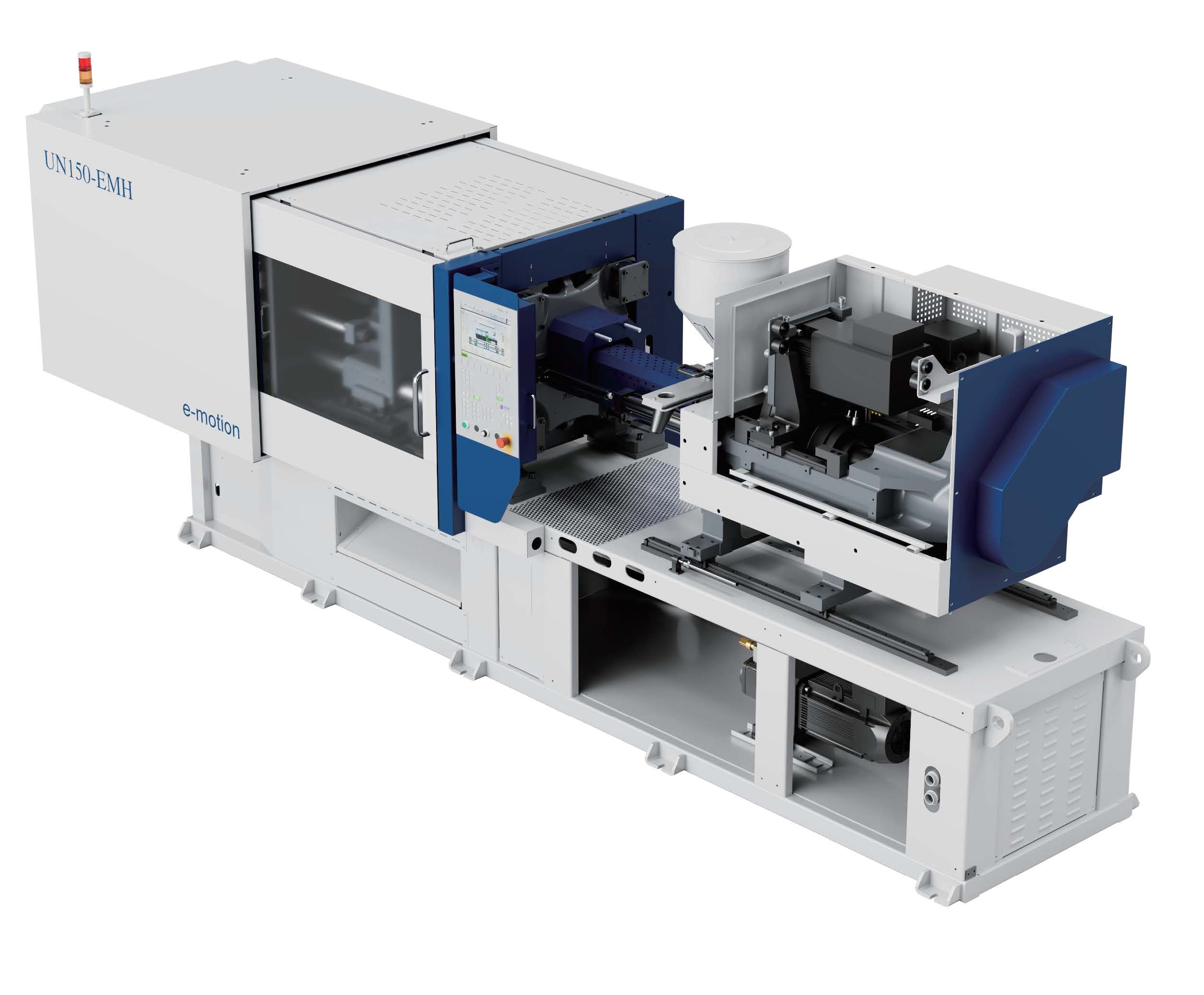

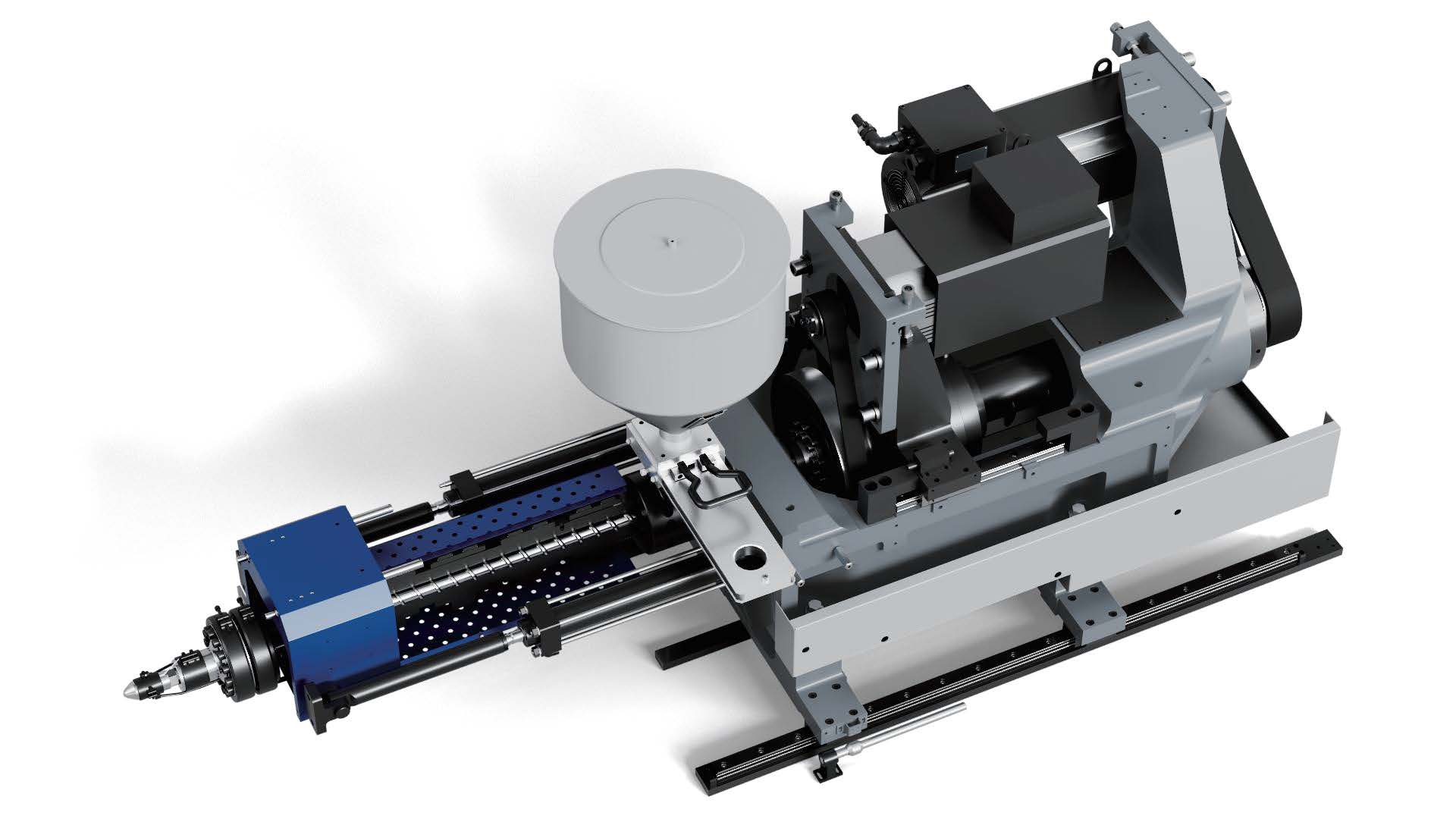

Hybird Injection molding Machine

Capacity:150 Ton~450 Ton

The EMH Series Hybrid Injection Molding Machine is a state-of-the-art solution designed for precision, efficiency, and reliability. With advanced features and a robust design, it meets the demands of modern manufacturing, ensuring high-quality production and energy savings.

Description

Key Features

Injection Position Accuracy: 0.02mm

Position Accuracy of Opening and Closing Die: 0.1mm

Product Repetition Accuracy: 7‰ – 0.1

High Response and Precision

- Maximum Injection Pressure: Greater than 3000Bar (suitable for A screw, below D45 screw)

- Response Speed: 30ms (suitable for A screw, below D45 screw)

- Double “Clean” Technology: Ensures cleanliness and energy efficiency

- CPK: ≥ 1.67, with low residual injection screw

- Standard Compliance: Adheres to German Industry 4.0 standards with intelligent PID adjustment for precise injection control, enabling the realization of a digital intelligent factory

Industry Expertise

- Experience: Over 60 years of deep industry experience

- Comprehensive Specifications: Wide range of specifications to meet diverse needs

Control Unit

- Advanced Controller: Standard KEBA 12″ Keplast i1180-0110-00 large screen controller with a user-friendly UI interface

- Industry 4.0: Compliant with German Industry 4.0 standards for digital and intelligent factory production

- Stable Back Pressure: Equipped with loadcell sensor for real-time monitoring and closed-loop control, ensuring stable back pressure during the melting process

Precision Control

- Real-Time Monitoring: lo15adcell sensor monitors barrel pressure in real-time

- Accurate Pressure Control: Achieves pressure control within ±1bar during the pressure holding stage

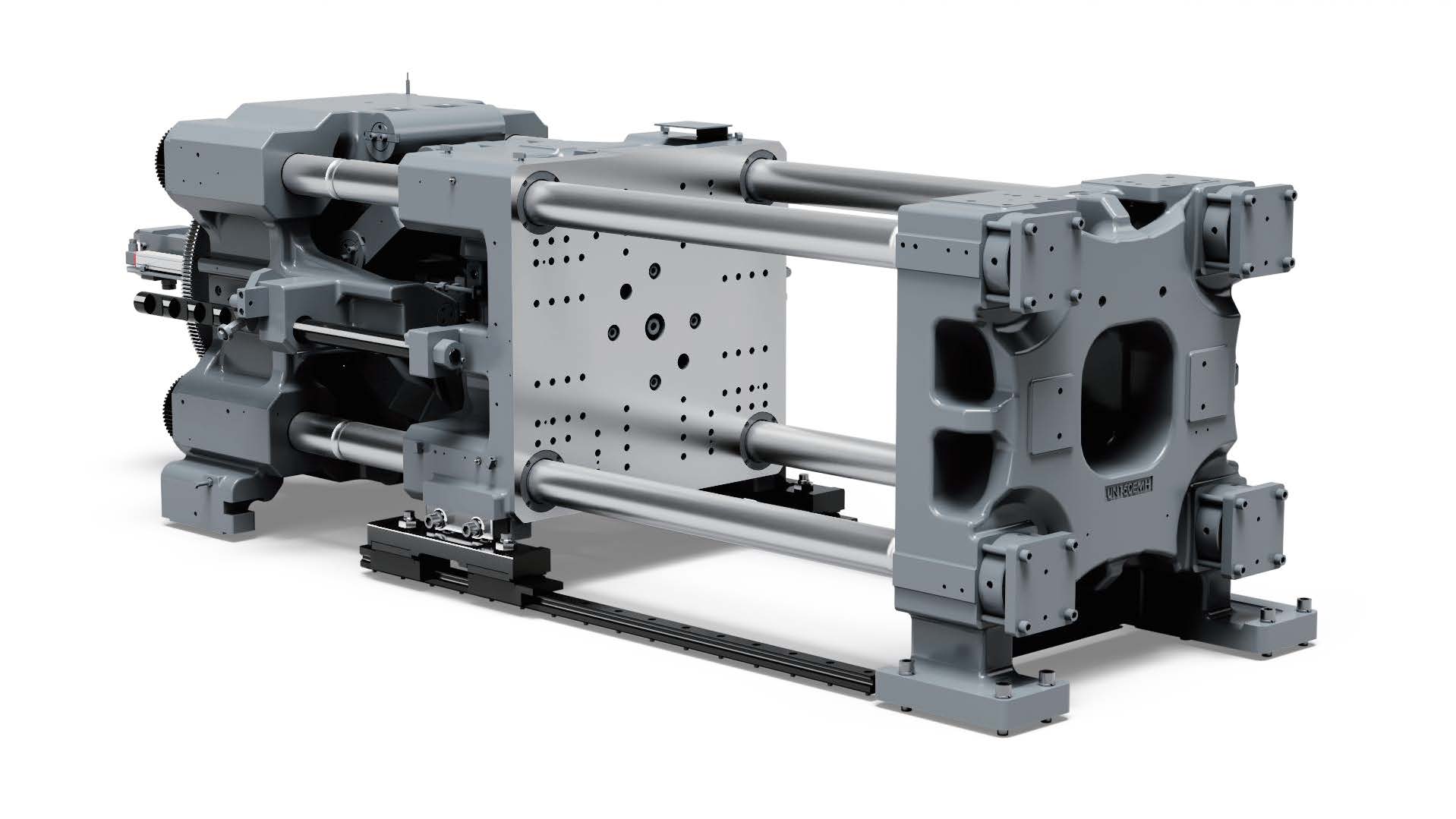

Mode-Locking Unit

- High Precision and Strength: Features a linear slide rail for high precision and strength

- European Design: Portable ejection structure design for ease of use

- High Rigidity Template: Includes automatic mold adjustment function for consistent performance

- High Speed and Rigidity: Mold locking device with high-speed and high-rigidity cylinder

- Large Die Stroke and Bulk Modulus: Designed for versatility

- Tie Rod Distance: Provides large inner distance under the same tonnage

- Centralized Lubrication: Quantitative centralized lubrication device for efficient maintenance

- Safety Devices: Includes both mechanical and electrical safety devices for reliable operation

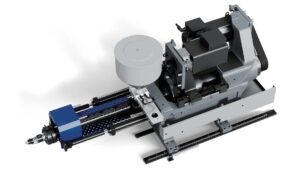

Injection Unit

- Integrated Structure: Double screw integrated injection structure for enhanced performance

- Temperature Control: SSR drum temperature control system for precise temperature management

- Automatic Cleaning: Features an automatic cleaning circuit

- High Response Device: High response ball screw belt drive injection device for fast and accurate operation

- Precision Screw: Imported high precision ball type screw

- Innovative Design: Plasticizing system developed by a Japanese team

- Enclosed Structure: Fully enclosed sheet metal structure for dustproofing, noise reduction, and easy cleaning

- Real-Time Monitoring: Visualization and graphical display of production injection parameters for high efficiency and precision

Oil-Electric Mixing

- Servo Hydraulic Pump: Built-in motor with servo hydraulic pump for high speed, efficiency, and energy savings

- Position Feedback: Motor equipped with an absolute value encoder for reliable position feedback

- Servo Control: Injection and melt speeds controlled by servo motor for high precision, with injection position control accuracy up to 0.01mm

Customized services for specific product and Sector, Such as

Two Color Machine

C Type Machine

Glass Fiber

Bakelite Machine

Zipper Machine

Horizontal clamping & vertical injection machine

Umbrella machine etc.