HORIZONTAL SILICONE INJECTION MOLDING MACHINE

Capacity:200Ton~800 Ton

Enhance your manufacturing capabilities with our cutting-edge Horizontal Silicone Injection Molding Machine, designed for precision, efficiency, and versatility in silicone rubber production.

Description

Benefits & Features

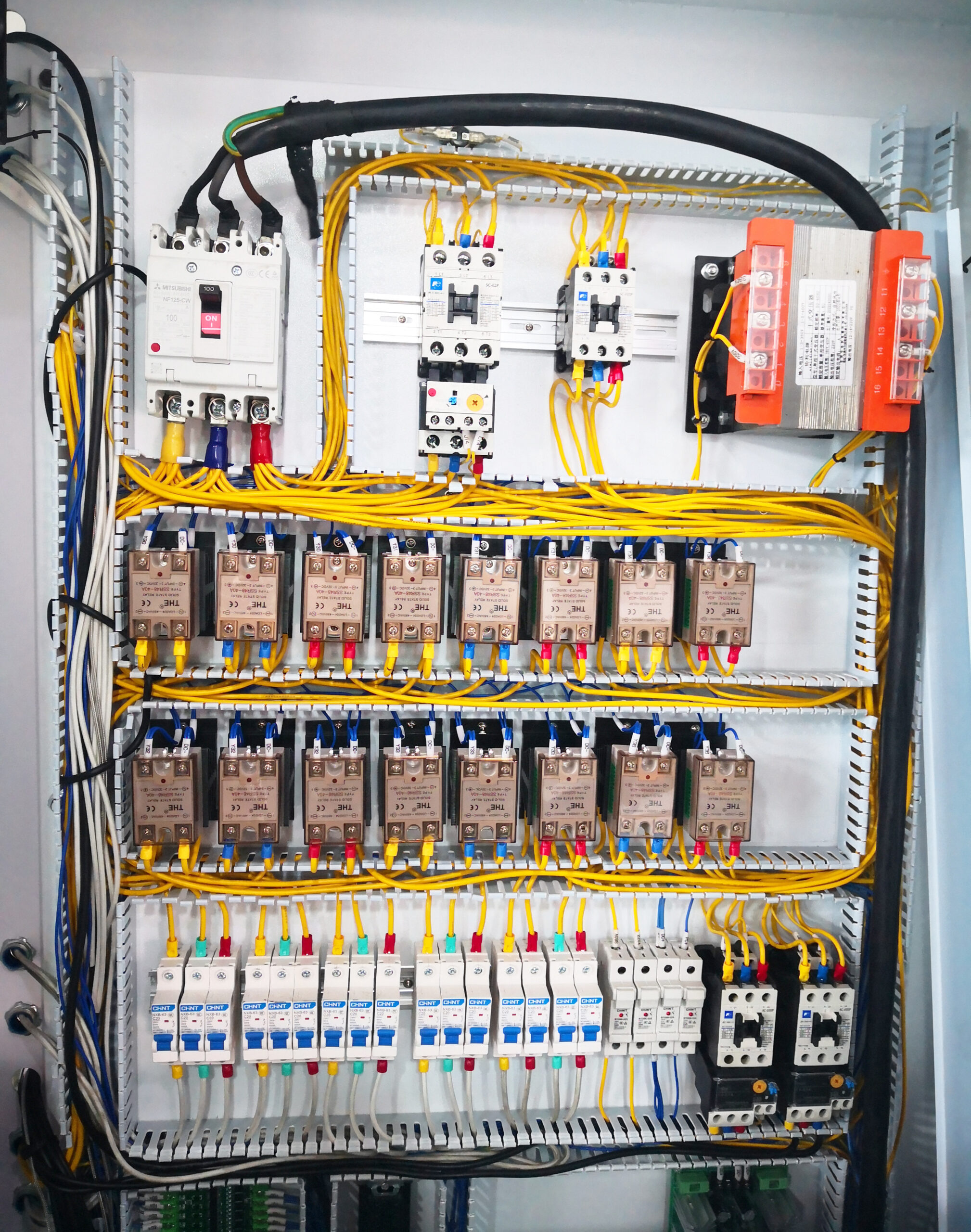

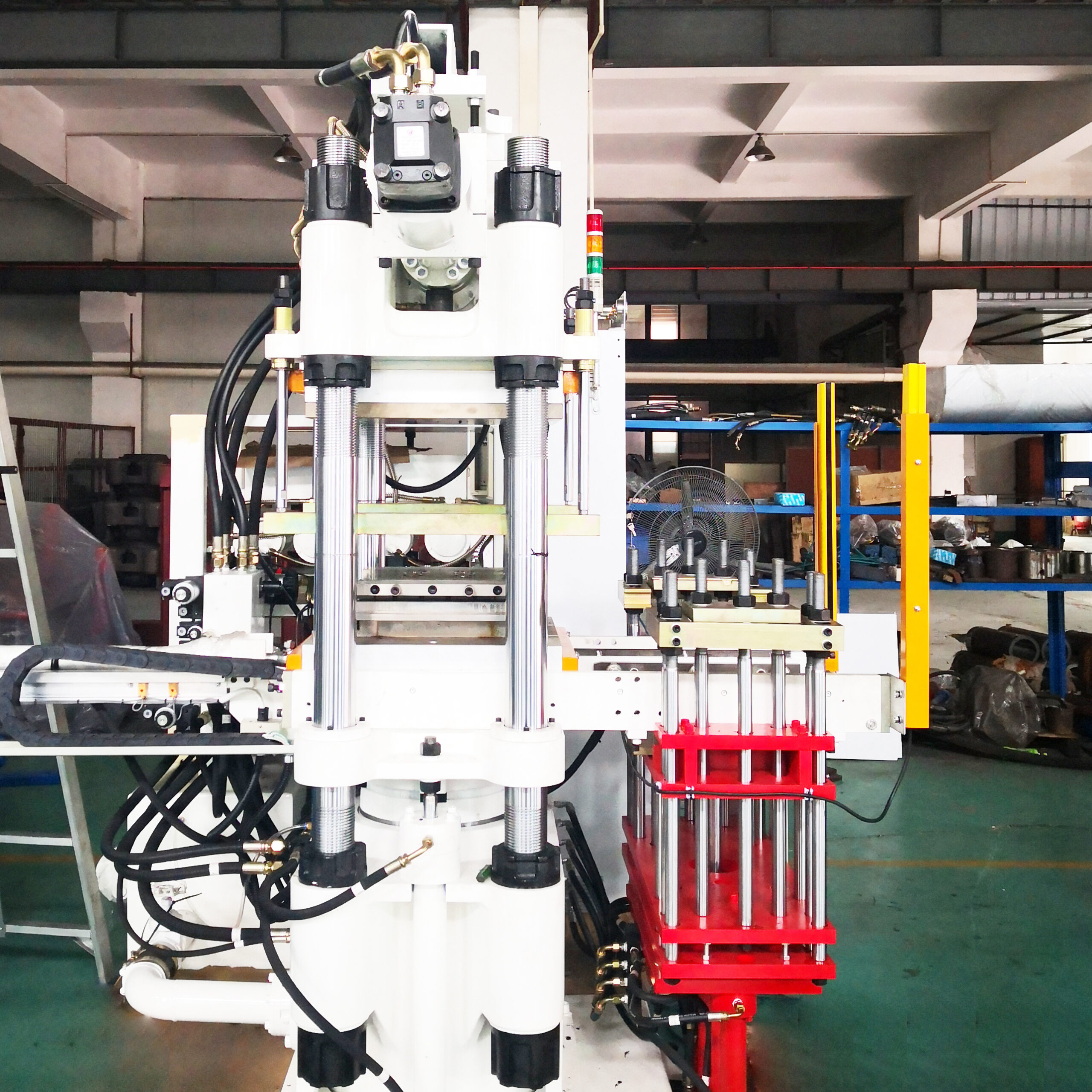

Introducing our cutting-edge Horizontal Injection Molding Machine, specifically designed to elevate the production of various rubber parts. This machine stands out with its adjustable capabilities, allowing precise control over curing and injection speeds to accommodate multiple requirements. A standout feature is the patented anti-damage misalignment function, ensuring the protection and longevity of the molding. The machine offers three stages of pressure and speed adjustments for mold opening and closing, providing unparalleled precision in the molding process.

Suited primarily for the production of all types of rubber parts, this machine boasts a horizontal first-in-last-out injection structure, optimizing the material usage and enhancing the quality of the final product. This design also facilitates easier maintenance and accessibility. Ideal for manufacturers seeking efficiency, precision, and safety in rubber parts production, our Horizontal Injection Molding Machine represents a significant advancement in molding technology.

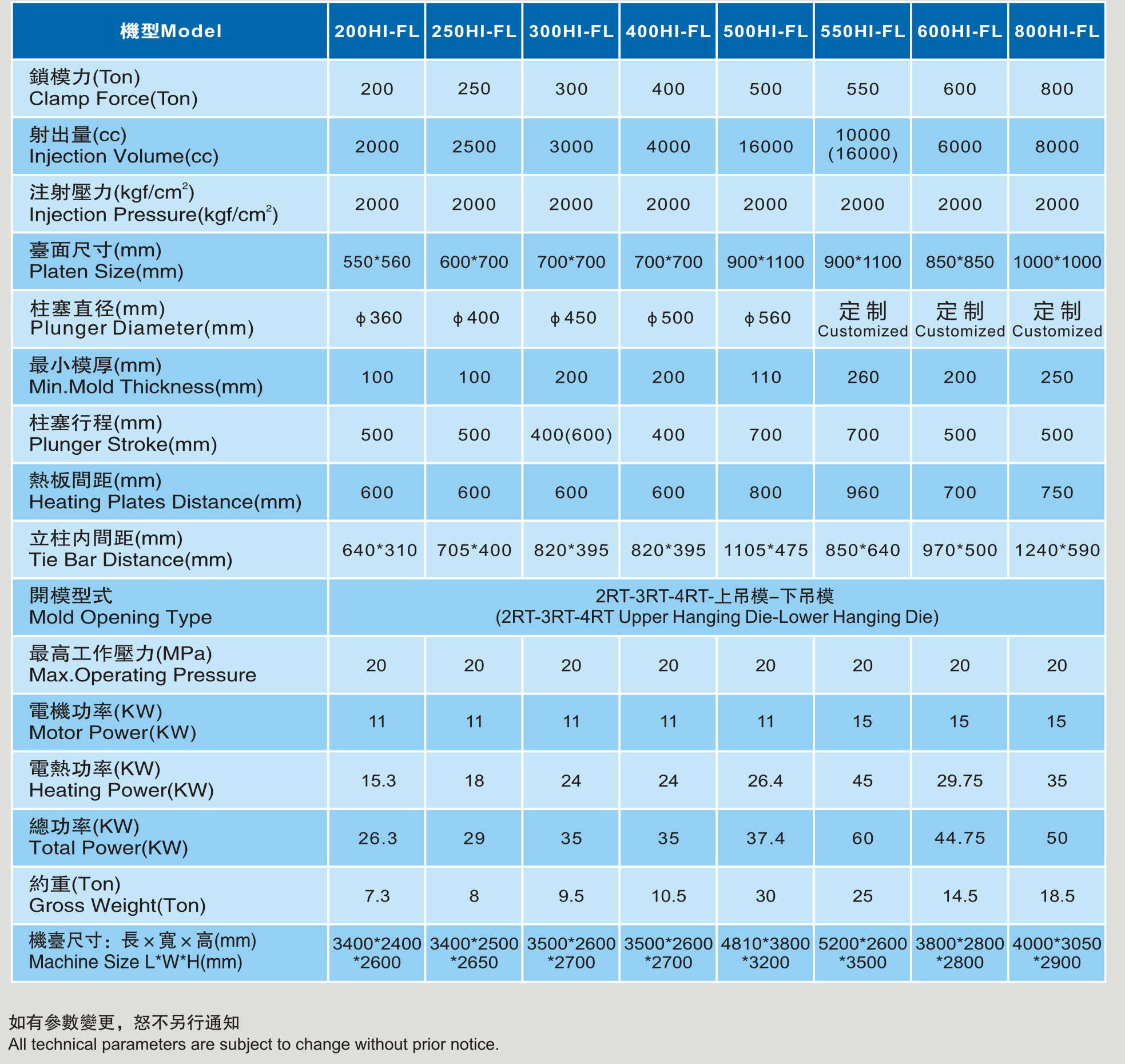

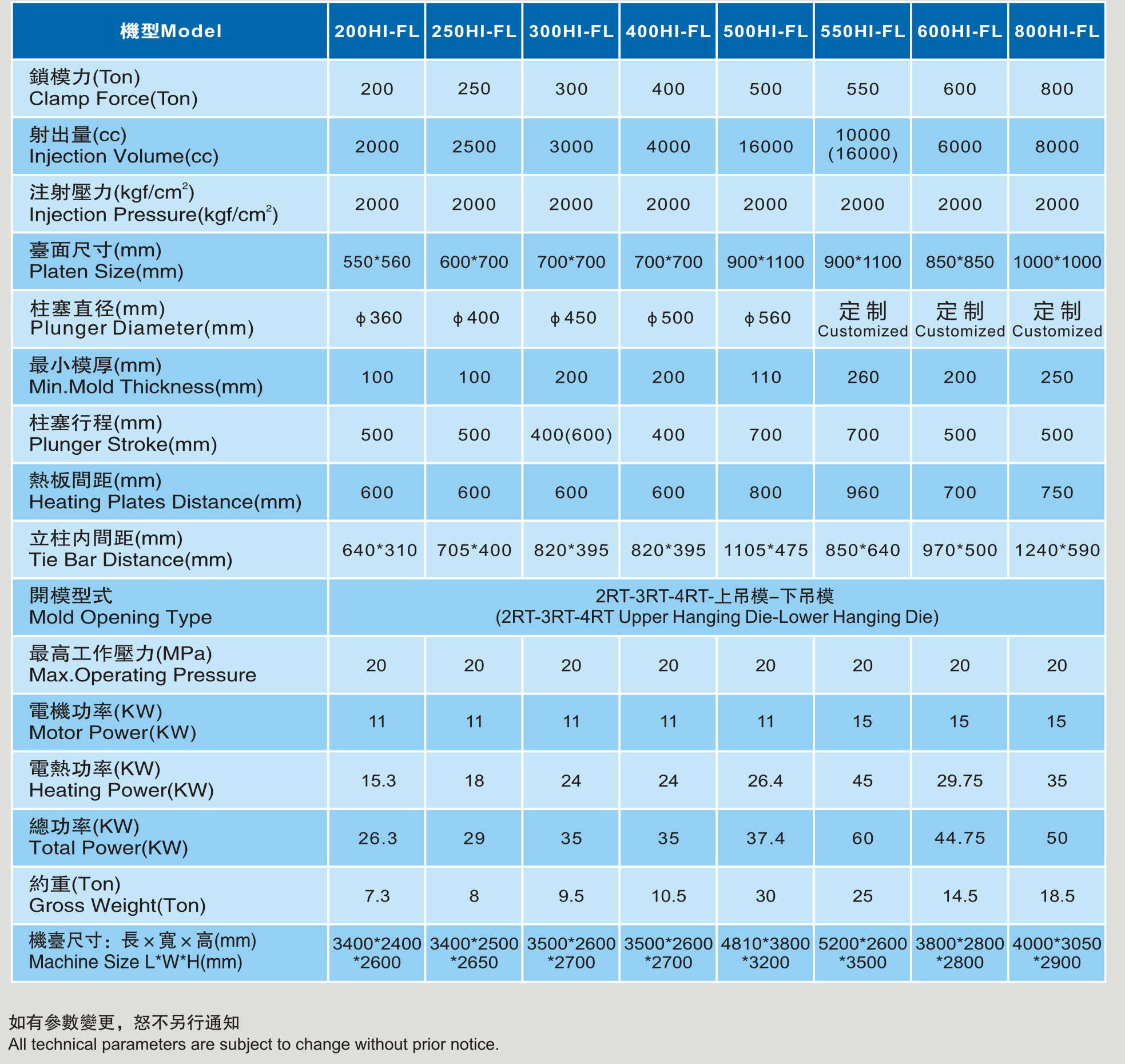

Main technical parameters

Specs

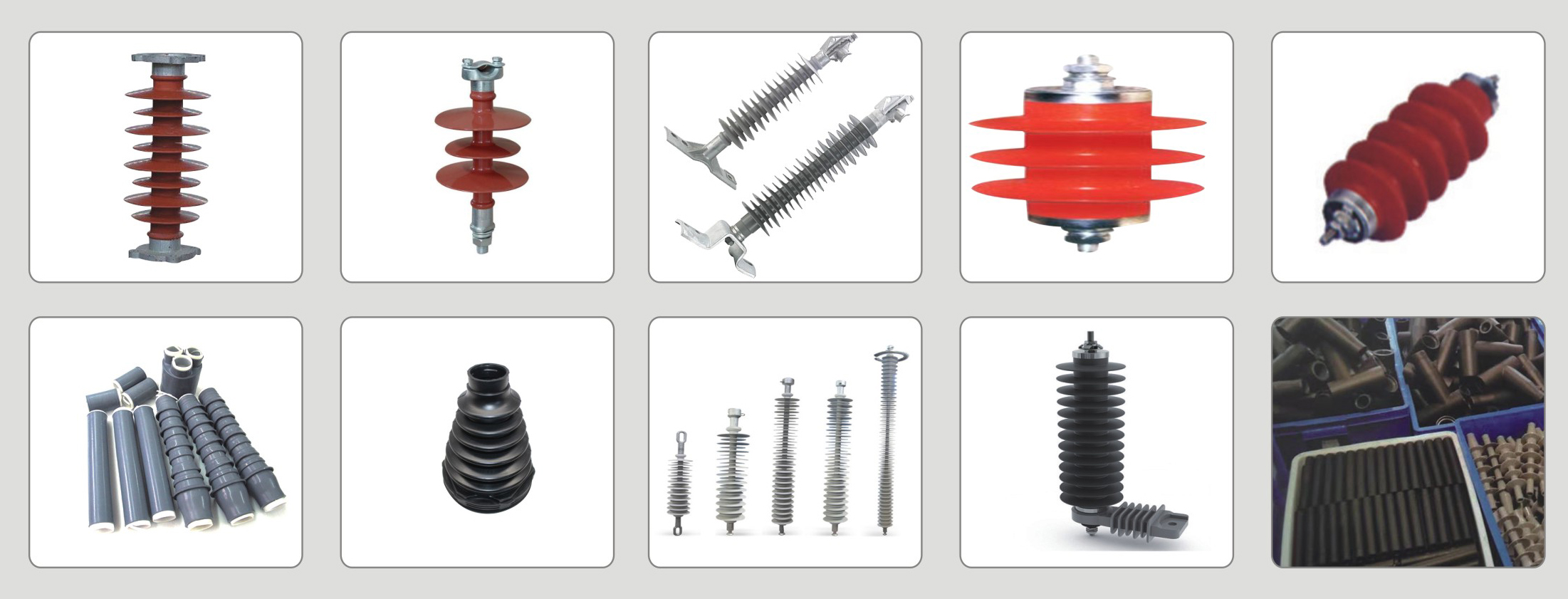

Cases

Application Category

Other Cases

Machine Disptach

Comments