High speed 4 stations injection stretch blow molding machine

Model:JA-160-V4

Clamping force:280KN

Elevate your production capabilities with our cutting-edge High-Speed 4-Station Injection Stretch Blow Molding Machine. This state-of-the-art equipment is designed to revolutionize your manufacturing process, from raw materials to finished products.

Description

Benefits & Features

“Introducing the Future of Blow Molding: The High-Speed 4-Station Injection Stretch Blow Molding Machine”

Elevate your production capabilities with our cutting-edge High-Speed 4-Station Injection Stretch Blow Molding Machine. This state-of-the-art equipment is designed to revolutionize your manufacturing process, from raw materials to finished products.

**Key Features and Benefits:**

1. **Compact Design:** Our machine’s compact nature significantly reduces the need for additional equipment. It incorporates all processes from injection to blowing, thereby saving on equipment costs and optimizing workshop space.

2. **Energy Efficiency:** With an innovative design that eliminates the need for secondary heating of preforms, this machine can save about 30% in power consumption. This energy-saving system not only cuts costs but also supports sustainable manufacturing practices.

3. **Clean Production Process:** The entire process, from preform forming to bottle blowing, is conducted in a single machine. This integration minimizes the risk of contamination during transportation, ensuring a cleaner and more reliable production line.

4. **Stability and Quiet Operation:** Experience stable mechanical operation with minimal noise, enhancing the work environment and ensuring consistent product quality.

5. **Fully Automated System:** Our machine’s fully automated production eliminates the need for manual intervention in processes like burr removal and preform transportation, significantly reducing raw material and labor costs.

6. **High-Quality Production:** It ensures perfect bottle neck size and clean parting lines, resulting in stronger and more reliable bottles.

7. **User-Friendly Operation:** Equipped with a built-in error detection and alarm system, the machine is easy to operate, with clear instructions displayed on the control screen.

8. **Versatile Applications:** Capable of handling a range of sizes from 5ml to 2500ml and compatible with materials like PET, PETG, TRITAN/PCTG, PP, and PC, this machine is versatile enough to meet diverse industry needs.

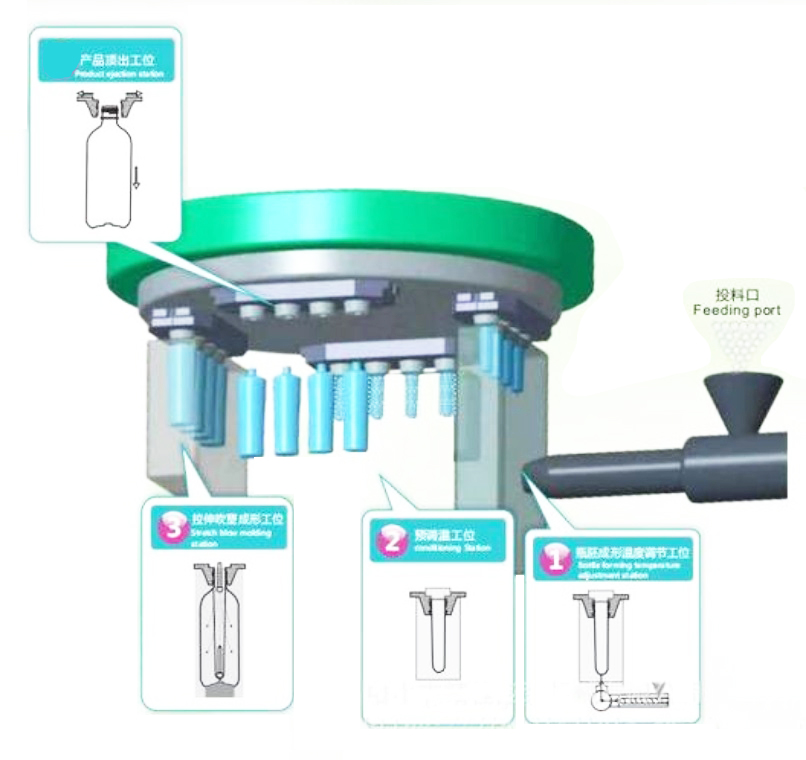

**Innovative 4-Station Production Process:**

1. **First Station:** Injection of plastic particles into the mold cavity to form a precise and stable preform.

2. **Second Station:** A 90-degree rotation brings the preform to the temperature/blowing station for precise temperature adjustment and shaping before blowing.

3. **Third Station:** Another rotation leads to the stretch and blow station, where the preform is blow molded into the container.

4. **Fourth Station:** A final rotation for ejecting the completed containers, marking the end of the production cycle.

Transform your production with the High-Speed 4-Station Injection Stretch Blow Molding Machine – the perfect blend of efficiency, quality, and innovation. Contact us for a demo and see how this machine can redefine your manufacturing process.

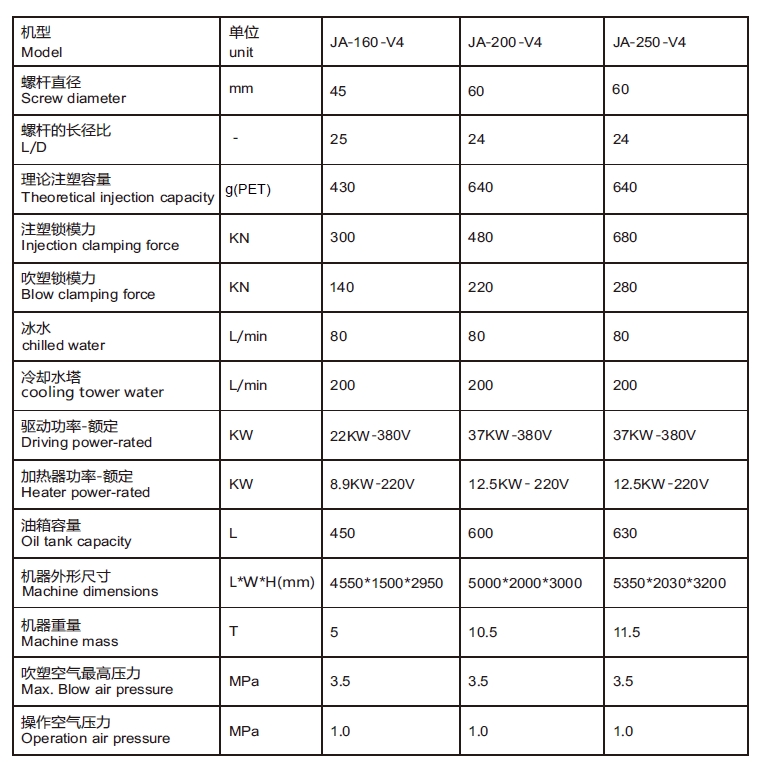

Specs

*The parameters are for reference only, please contact your sales representative for details.

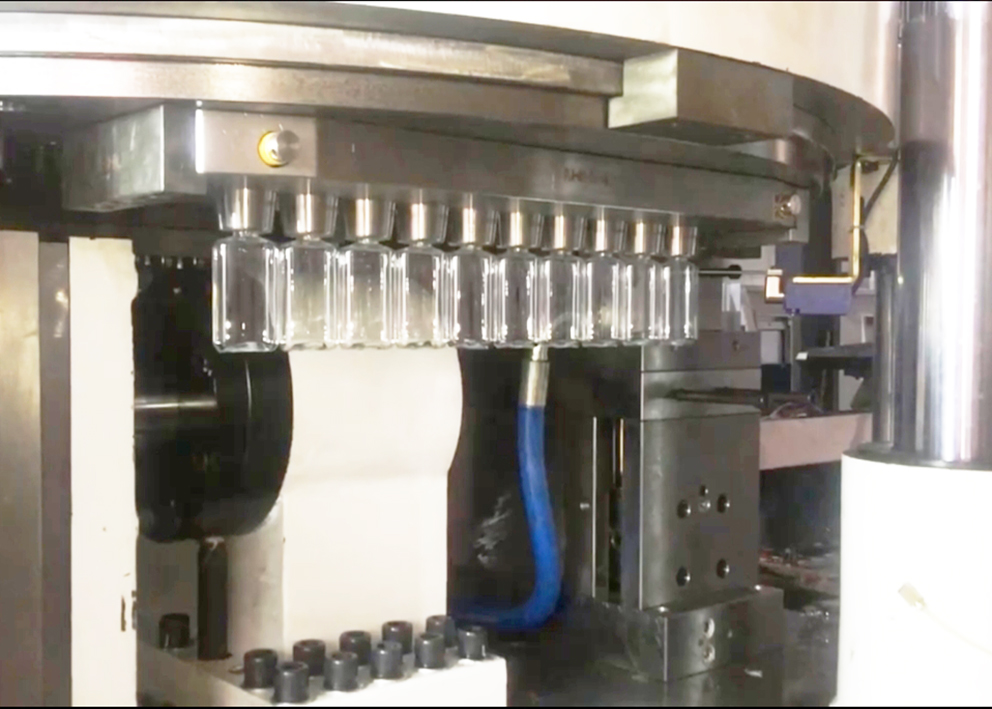

Cases

Application Category

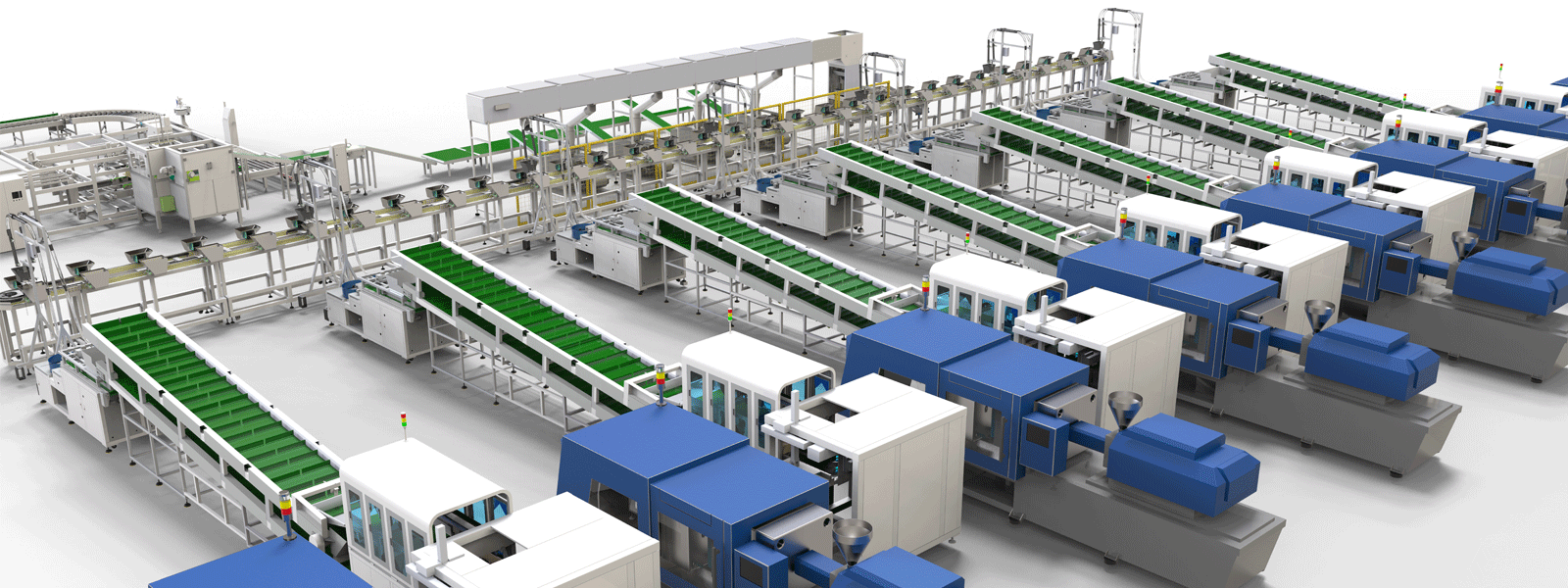

Machine Disptach

Comments