With the intensification of market competition, most packaging industries have stricter requirements on food safety, especially for food packaging industry, Such as :

1.Oil-free, No oil leaks and spills on the floor.keep the workshop clean.

2.High-efficiency, high injection speed improve the machine efficiency.

3. Energy-saving etc.

This are the reasons why Electric injeciton molding machine is widely used at packing Sector

1 Yogurt Cup

Model: 360 Ton

Cavity: 8 ; Material: PP

Cycle Time: 1 out of 8 (5.8S ) + in-mold labeling = 6.5 seconds

Capacity: 110,000 Pcs / day.

2. Cap

3. Disposable Cup

4. Coffe Cup

5. Food Container

” Why Electric Injection Molding Machine save power for your factory ?”

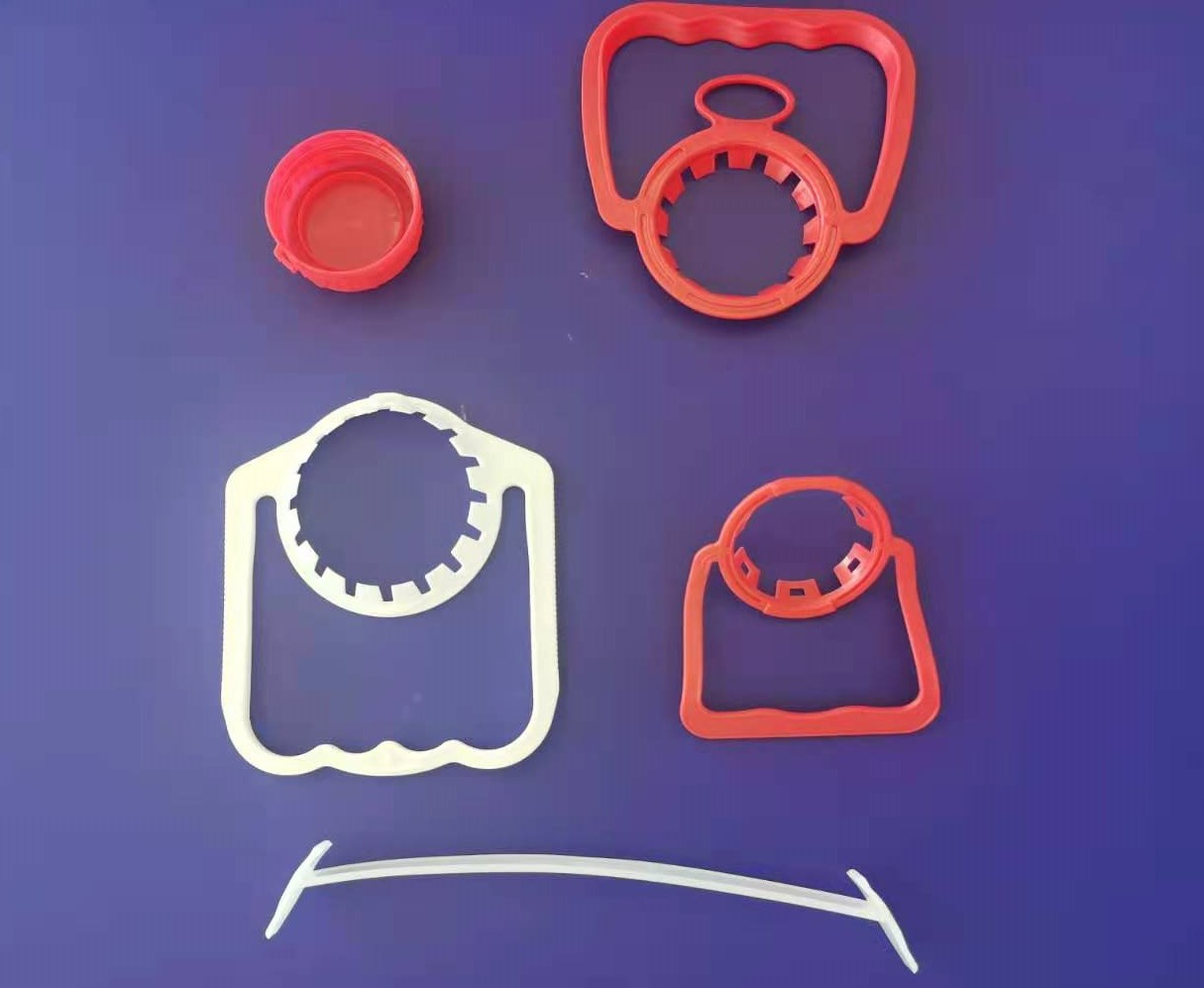

6. Handle

7. Bucket

Conclusion

Using an all-electric injection molding machine, you will continue to run production without oil, less maintenance, higher accuracy, higher repeatability, energy saving, a quieter working environment, and a machine that is easier to maintain.

SANTSAI MACHINERY can provide a complete turn key solution including machines, molds, auxiliary and automation equipment. Contact us today to request more information and a proposal for your project.

Other Cases

More sector Application cases as follow.